The Automatic Kit Assembly Leak Detector is a highly efficient, intelligent device designed specifically for in vitro diagnostic (IVD) kit production, integrating automated assembly and airtightness

The Automatic Kit Assembly Leak Detector is a highly efficient, intelligent device designed specifically for in vitro diagnostic (IVD) kit production, integrating automated assembly and airtightness testing.

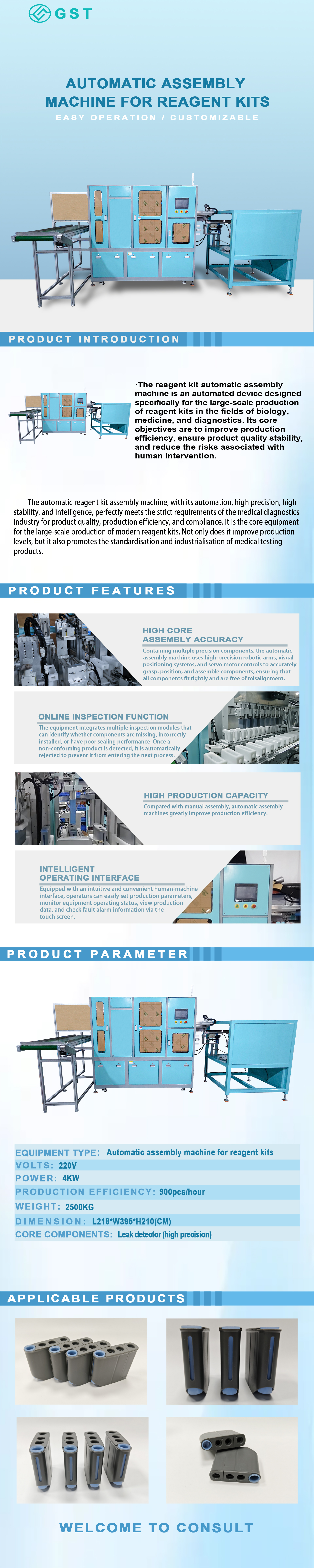

This device completes the entire kit production process, from component loading and precise assembly to leak testing, ensuring efficient production while meeting strict quality control standards. Compared to manual assembly, the Automatic Kit Assembly Leak Detector not only significantly increases production speed but also uses intelligent sensing and pressure detection systems to monitor leaks or seal defects in real time, ensuring the stability and reliability of the kits.

The device boasts a rational design and easy operation, supporting the customization of a wide range of kit models to meet the production needs of diverse companies. Its automated and intelligent application effectively reduces labor costs and improves production consistency, making it ideal for manufacturers of medical consumables such as diagnostic reagents and in vitro diagnostic (IVD) tests.

Equipment Details:

Sizes: L396cm*W218cm*H210cm

Weight: 2500kg

Power: 4kW

Production Capacity: 900 units/hour

Voltage: 220V

Core Component: High-precision leak detector