The trouser hanger automatic assembly machine is a highly efficient automated device developed specifically for the garment accessories industry, capable of integrated assembly of trouser hangers fr

The trouser hanger automatic assembly machine is a highly efficient automated device developed specifically for the garment accessories industry, capable of integrated assembly of trouser hangers from component parts to finished products.

Utilizing advanced automatic feeding, positioning, and assembly technologies, this machine offers easy operation and stable performance, significantly improving production efficiency and reducing labor costs.

The trouser hanger automatic assembly machine features high assembly precision, fast speed, and consistent finished products. It also supports flexible switching between multiple trouser hanger sizes to meet the production needs of diverse customers.

Whether operating in large-scale factories or small and medium-sized enterprises, the use of a trouser hanger automatic assembly machine can effectively optimize production processes, improve product quality, and enhance market competitiveness.

Machine Description:

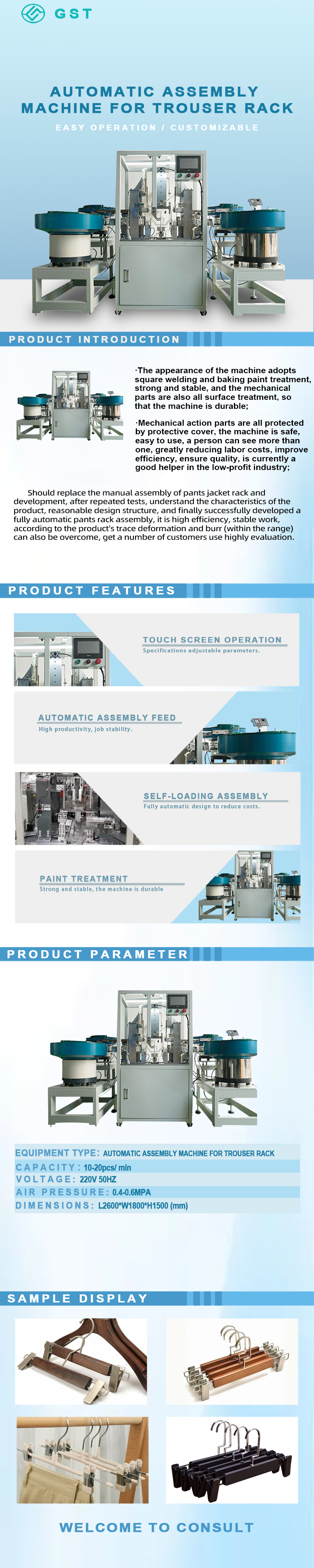

This machine should replace the manual assembly of pants clip hanger and development, after repeated tests, understand the characteristics of the product, reasonable design structure, and finally succeeded in the development of fully automatic pants hanger assembly, it is highly efficient, stable work, according to the product's trace deformation and burr (within the range) can also be overcome, and has been used by a number of customers to use the high evaluation; first of all, manual hanger rod hanged to the machine on top of the sliding rod, the machine is automatically a First of all, manually hang the hanger rod to the machine above the sliding pole, the machine will automatically arrange one by one next to the fixture, and then put the hanger clip and iron clip into the vibrating disk inside the automatic arrangement out, the homemade manipulator puts the hanger rod into the fixture, the fixture fixes the hanger, and then transports the fixture, and the homemade manipulator puts the clip into the fixture, and then the manipulator removes the iron clip to assemble the assembled finished product by the manipulator to automatically pick up the hanger and hang it on the sliding pole, and the manpower only needs to add and collect the material;.

The appearance of the machine adopts the square welding and baking paint treatment, solid and stable, mechanical accessories are all surface treatment, so that the machine is durable, mechanical action parts are all protected by the protective cover, high machine safety, easy to use, a person can look at more than one, greatly reducing the labor cost, improve efficiency, quality assurance, is currently a low-profit industry a great helper.

Technical parameters:

Voltage: 220V AC 50HZ

Air pressure: 0.4-0.6MPA

Working efficiency: 10-20/minute

Dimension: L2600*W1800*1500H