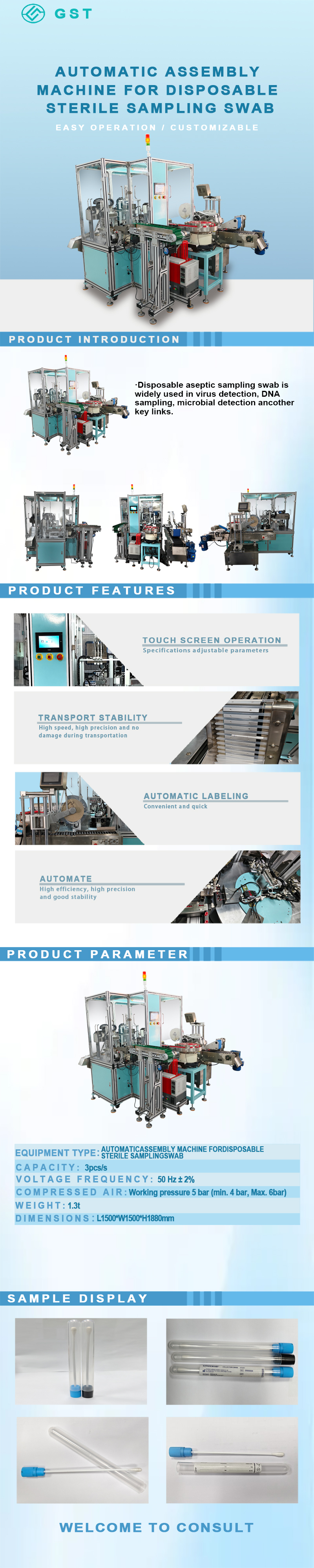

The Disposable Swab Automatic Assembly Machine is an integrated production machine designed specifically for the medical device and in vitro diagnostic industries. It is primarily used to automatica

The Disposable Swab Automatic Assembly Machine is an integrated production machine designed specifically for the medical device and in vitro diagnostic industries. It is primarily used to automatically load, align, assemble, secure, and inspect swab shafts, cotton tips, cannulas, and packaging components. Designed to improve production efficiency, ensure cleanliness, and consistency, this equipment complies with modern medical consumable production standards.

Key Functions and Technical Features:

Automatic Loading and Sorting: Utilizing a vibrating plate or hopper feeding system, swab shafts, cotton tips, cannulas, and other components are sorted and conveyed separately, ensuring stable delivery to the assembly station.

High-Precision Alignment Assembly: Using a positioning fixture and servo control, components are precisely docked, plugged, or pressed together, ensuring assembly quality and consistency.

Hot Melt/Adhesive Bonding: Hot melt or adhesive bonding is used to secure the cotton tips to the shafts and cannulas, ensuring a secure, loose structure.

Online Inspection and Rejection: A vision system or photoelectric inspection device inspects the assembled swabs for appearance, tightness, and assembly integrity. Any abnormal product is automatically rejected.

Intelligent Control System: Based on a PLC + HMI control platform, users can set production parameters, monitor assembly status, adjust speed, and generate alarms via the touchscreen.

Clean and Anti-Contamination Design: Key components and swab contact areas are constructed of stainless steel or corrosion-resistant materials, resulting in a compact and easy-to-clean structure, reducing contamination risks.

Modular Design and Compatibility: Each functional module (loading, assembly, inspection, and discharge) can be independently maintained, and fixtures can be replaced or parameters adjusted to suit different swab specifications.

Application Value and Competitive Advantages:

Significantly Improved Efficiency: Compared to manual assembly, this device achieves high-speed, stable, and continuous output, significantly increasing production capacity.

Quality Consistency: Automated assembly and inspection reduce human error, improving product quality and yield.

Cost Savings: Reduced labor input and rework rates lower operating costs.

Meets Standardized Production Needs: It complies with the cleanliness standards and quality requirements of the medical device and IVD industries, making it a key piece of equipment for modern smart factories.

Full-Line Integration: It can be integrated with upstream swab cutting, dust blowing, sterilization, and packaging equipment to create an automated swab production line.

In short, the disposable sampling swab automatic assembly machine is a significant innovation in the field of medical consumables automation, enabling companies to significantly increase production capacity, ensure quality, and reduce costs. It is an ideal choice for modern swab manufacturers pursuing automation and intelligent upgrades.

Equipment Details:

Model Number: GST-CYSZ01A

Sizes: L150cm*W150cm*H188cm

Weight: 1300kg

Power: 3KW

Production Capacity: 180 PCS/minute

Voltage: 220V/50Hz

Core Components: Motor, hot melt unit

Customized Support: Yes