The automatic facial mask filling machine is a high-precision automated packaging device specifically developed for the cosmetics and skincare industries. It is primarily used for fully automated fi

The automatic facial mask filling machine is a high-precision automated packaging device specifically developed for the cosmetics and skincare industries. It is primarily used for fully automated filling, sealing, and inspection of products such as bagged facial masks, essence masks, and medical dressings.

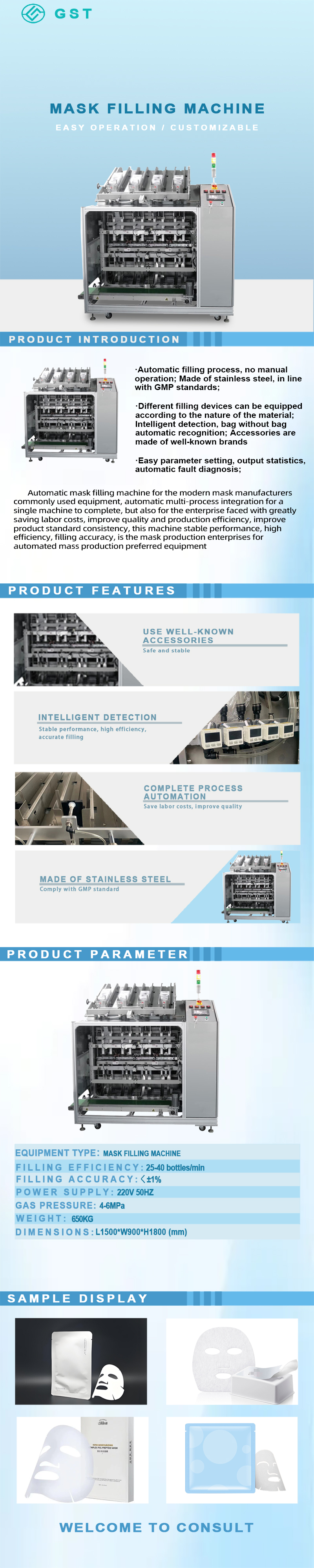

The machine integrates an intelligent control system, a high-precision metering pump, and an efficient packaging module to achieve precise quantitative filling, automatic sealing, and quality inspection of facial mask liquids, effectively improving production efficiency and product consistency.

The machine is constructed of food-grade stainless steel and meets GMP clean design standards. The filling unit utilizes an imported servo drive and a high-precision flow control system to ensure that each bag is filled with accurate, leak-free, and contamination-free facial mask liquid.

After filling, the system automatically performs operations such as sealing, date coding, and batch number recognition. The entire process is centrally controlled by a PLC and human-machine interface (HMI), ensuring easy operation and stable operation.

The automatic facial mask filling machine supports a variety of packaging specifications and bag types (such as aluminum foil bags, stand-up pouches, and custom-shaped bags). It can flexibly switch molds and parameters according to customer needs, enabling a single machine for multiple uses. The equipment can also be equipped with modules for automatic loading, labeling, and cartoning, creating a fully automated facial mask production and packaging line to meet diverse production capacity and process requirements.

To ensure packaging quality and product safety, the system features multiple built-in inspection functions, including bag opening detection, fill level detection, seal integrity detection, and automatic rejection of defective products, fully guaranteeing a high yield of finished products. All key components are from leading international brands, ensuring long-term reliability and stability.

This automatic facial mask filling machine is widely used in the cosmetics, medical aesthetics, pharmaceutical, and daily chemical industries. CE and ISO certified, it supports custom customization and complete line integration, helping companies build digital, unmanned, intelligent production workshops and achieve higher production efficiency and brand competitiveness.

Technical parameters:

Model Number: GST-SWYP006A

Filling efficiency: 25-40 bottles/minute;

Filling accuracy: <±1%;

Power supply: 220V 50HZ;

Air pressure: 4-6MPa;

Dimensions: 1500*900*1800mm;

Mass: 650KG.

Customized Support: Yes