The automatic cream filling machine is a fully automated filling solution specifically designed for the mid-to-high-end cosmetics industry. It integrates high-precision metering, stable filling, and

The automatic cream filling machine is a fully automated filling solution specifically designed for the mid-to-high-end cosmetics industry. It integrates high-precision metering, stable filling, and flexible production, suitable for the automated production of various cream and lotion products such as face creams, lotions, serums, and eye creams, helping companies achieve simultaneous improvements in efficiency, quality, and brand value.

High-precision quantitative filling: Utilizing servo-driven piston pumps or precision gear pumps, combined with a pressure feedback system, the filling accuracy can reach ±0.5%, effectively controlling filling errors and material waste.

Wide material adaptability: Designed specifically for medium-to-high viscosity creams, it can stably fill products of different textures, from light lotions to thick creams (viscosity range 1,000-100,000 cP), without foaming or stringing.

Fully automatic and efficient production: Achieves integrated automatic bottle feeding, positioning, filling, and capping (optional) operations, with a maximum filling speed of up to 60 bottles/minute, increasing production capacity by more than 300% compared to semi-automatic equipment.

Pollution-free and clean design: A fully enclosed filling system combined with localized clean laminar flow protection; key contact parts are made of 316L stainless steel, meeting cosmetic GMP and ISO22716 certification requirements.

Flexible and intelligent control: User-friendly touch screen interface, supporting multiple formula storage and one-click recall, quick switching between different bottle types and capacities, with changeover time ≤15 minutes.

Constant pressure and constant speed filling technology: Real-time monitoring and adjustment of filling pressure and speed to ensure consistent filling lines and smooth surfaces for products of different viscosities.

Anti-oxidation and anti-contamination design: Optional nitrogen protection system to reduce the risk of product oxidation; the filling nozzle has anti-drip and automatic cleaning functions.

Visual positioning system (optional): CCD vision system for precise positioning of the bottle mouth, adapting to complex filling scenarios such as irregularly shaped bottles and irregular placement.

Data traceability and monitoring: Real-time recording of production process data, supporting statistical analysis of key indicators such as filling volume and pass rate, meeting production traceability requirements.

Technical parameters:

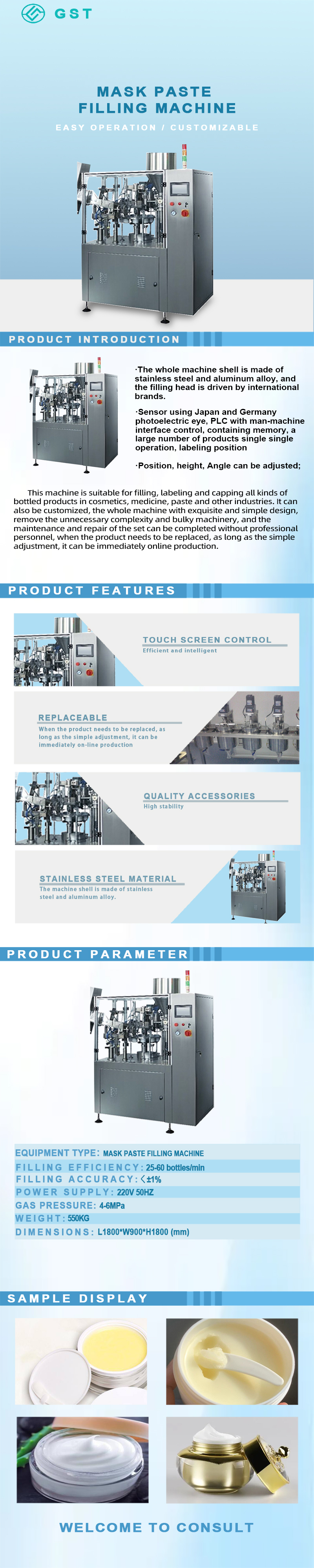

Model Number: GST-SWYP007A

Filling efficiency: 25-60 bottles/minute;

Filling accuracy: <±1%;

Power supply: 220V 50HZ;

Air pressure: 4-6MPa;

Dimensions: 1800*900*1800mm;

Mass: 550KG.

Customized Support: Yes