This automatic labeling machine for curved bottles is specifically designed for the automated labeling of cylindrical, flat, and irregularly shaped bottles and other curved containers. The equipment

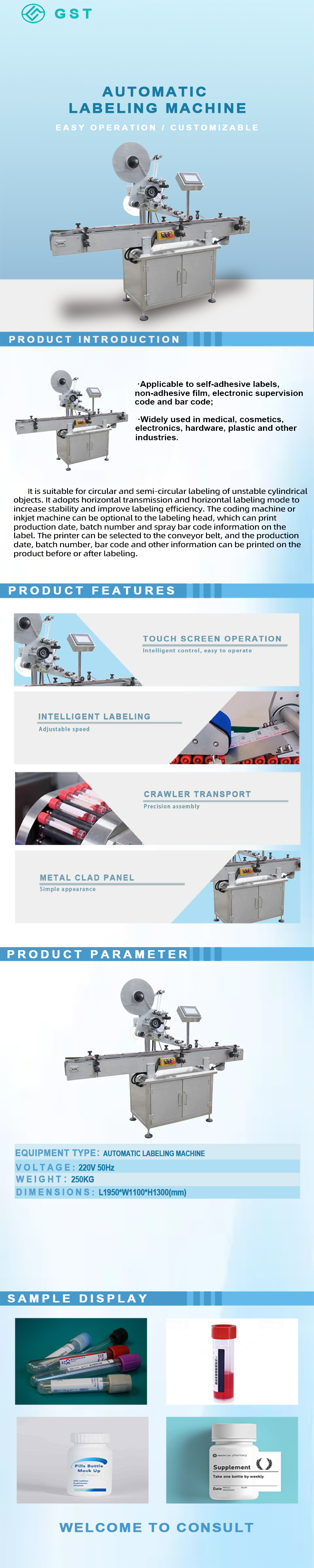

This automatic labeling machine for curved bottles is specifically designed for the automated labeling of cylindrical, flat, and irregularly shaped bottles and other curved containers. The equipment integrates visual positioning, flexible pressure application, and dynamic correction technologies to achieve precise, high-speed, and bubble-free labeling of full-circumference/half-circumference labels, positioning labels, and double-sided labels on various curved bottle surfaces. It is widely used in the beverage, daily chemical, pharmaceutical, and condiment industries.

Three-Dimensional Curved Surface Adaptive Labeling: Utilizing a servo-driven flexible pressure labeling system and dynamic tension control, it perfectly adheres to various curved surfaces with R≥15mm, eliminating wrinkles and bubbles, with a labeling accuracy of ±0.5mm.

Intelligent Visual Precise Positioning: Equipped with a high-resolution vision system, it real-time detects bottle position and angle, automatically corrects and compensates, achieving a positioning accuracy of ±0.3mm, and supports positioning and labeling of irregularly shaped bottles.

High-Speed and Efficient Operation: The labeling station and conveying system work synchronously, achieving a labeling speed of up to 400 bottles per minute, and supporting various label materials including self-adhesive labels, shrink film, and in-mold labels.

Flexible and Fast Changeover: Modular fixtures and a parameterized recipe system allow for changeover adjustments in ≤10 minutes; optional modules for inkjet printing, inspection, and code reading are available, enabling integrated labeling and coding.

Technical parameters:

Model Number: GST-BC003

Sizes: L1950*W1100*H1300(mm)

Production Capacities: 100pcs/min

Power (Output): 220V

Customized Support: Yes

Weight: 250KG