Release Date:2024-04-07 14:59:15 Popularity:

With the rapid development of science and technology, automation technology is increasingly used in industrial production. As an important part of automated production, automatic assembly production lines not only improve production efficiency and reduce costs, but also inject more intelligent elements into industrial production. This article will delve into the working principles, advantages and future development trends of automated assembly lines.

1. Working principle

The automatic assembly production line is a production system that integrates a variety of automation equipment and robotic technology. Its working principle mainly includes the following links:

1. Parts supply: The first step in the automatic assembly line is to supply the required parts and materials to the production line. This may involve automatic feeding systems, silos or other automated equipment.

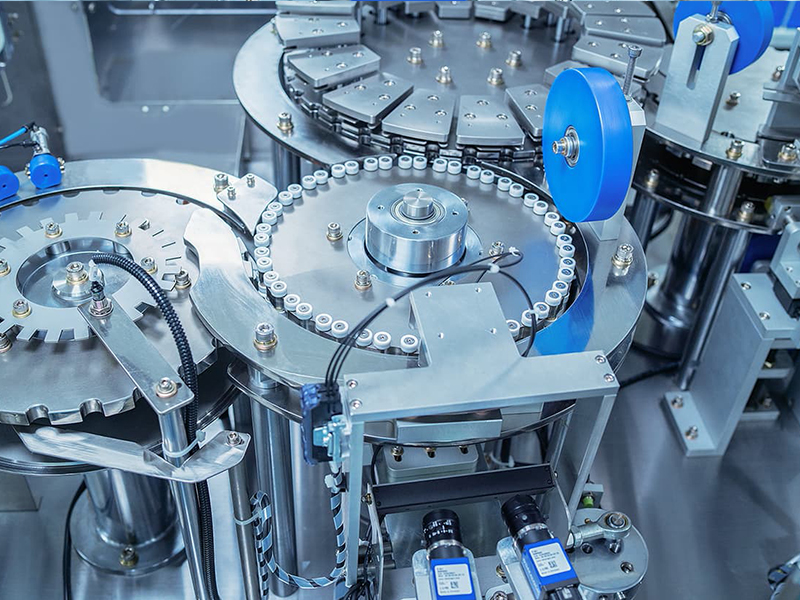

2. Assembly operations: Parts pass through various workstations on the production line, and each workstation is responsible for completing a specific assembly operation. These operations may involve the collaboration of automated equipment such as robotic arms, conveyor belts, and automatic positioning systems.

3. Quality inspection: After assembly is completed, quality inspection is usually required to ensure that the product meets the standards. Automatic assembly production lines can be equipped with visual inspection systems, sensors and other equipment to achieve automated quality inspection.

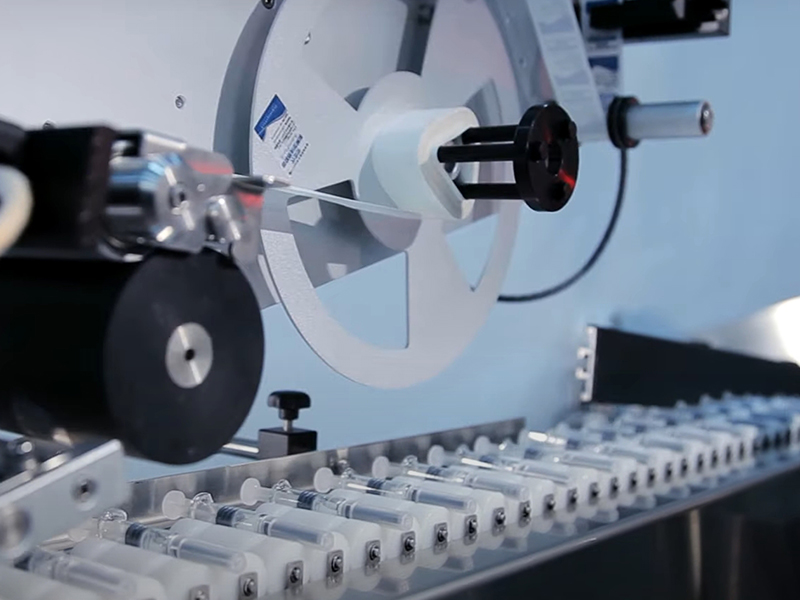

4. Packaging and labeling: Finally, the assembled products are packaged and labeled, usually through automated equipment, such as automatic packaging machines, inkjet printers, etc.

2. Advantages

Automatic assembly production lines have many advantages over traditional manual assembly lines, which are mainly reflected in the following aspects:

1. Improve production efficiency: The automatic assembly production line uses highly integrated automation equipment, which can achieve continuous and efficient production operations, greatly improving production efficiency.

2. Reduce labor costs: Compared with manual operations, automated production lines reduce dependence on manpower, reduce labor costs, and can work uninterrupted 24/7.

3. Improve product quality: The accuracy and stability of automation equipment can ensure product consistency and quality stability, and reduce product defects caused by human factors.

4. Flexibility and scalability: The automatic assembly production line can be flexibly adjusted and expanded according to production needs, adapting to different scales and types of production tasks.

3. Future development trends

With the continuous development of artificial intelligence, machine learning and other technologies, automatic assembly production lines are expected to show the following development trends in the future:

1. Intelligent and adaptive: Future automatic assembly production lines will be more intelligent, able to automatically adjust workflows and parameters according to different production environments and tasks to achieve adaptive production.

2. Collaborative robot technology: With the development of collaborative robot technology, future automatic assembly production lines will be more flexible, and robots and human workers can work more closely together to complete complex assembly tasks.

3. Data-driven optimization: Future automatic assembly production lines will collect a large amount of data and optimize it through data analysis and machine learning technology to further improve production efficiency and product quality.

4. Sustainable development: Future automatic assembly production lines will pay more attention to environmental friendliness and resource conservation, and adopt more energy-saving and environmentally friendly automation equipment and processes to achieve sustainable development.

As an important part of industrial automation, automatic assembly production lines are becoming an important carrier of industrial intelligence. Their efficient and precise production capabilities will bring huge changes and development to industrial production. With the continuous innovation and application of technology, it is believed that automatic assembly production lines will show more powerful production capabilities and more intelligent working methods in the future, providing more possibilities and opportunities for production in all walks of life.