Release Date:2024-06-27 14:01:14 Popularity:

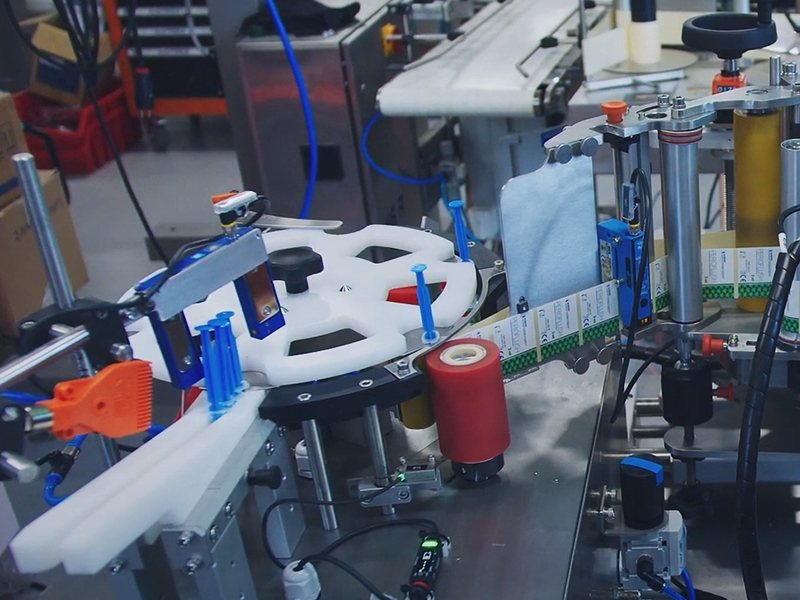

With the continuous advancement of science and technology, automation equipment has been widely used in various industries and has become an indispensable and important part of modern manufacturing. Automation equipment can achieve efficient, precise and flexible production operations by integrating advanced sensing technology, control systems and information technology. This article will explore the characteristics and advantages of automation equipment and analyze its profound impact on the development of manufacturing industry.

The main characteristics of automation equipment

1. Efficiency: Automation equipment can significantly improve production efficiency. They achieve continuous, high-speed production operations by optimizing process flows and equipment configurations. Automated equipment can complete a large number of production tasks in a short time, reducing manual operations and production waiting time.

2. Accuracy: Automation equipment is equipped with high-precision sensors and control systems, which can accurately control every production link to ensure the stability and consistency of product quality. The high-precision operation of automated equipment reduces human errors and improves product accuracy and consistency.

3. Flexibility: Modern automation equipment is highly adjustable and adaptable, and can quickly adjust and switch according to different products and market needs. By replacing molds, adjusting parameters and upgrading software, automation equipment can adapt to product production needs of various specifications and shapes.

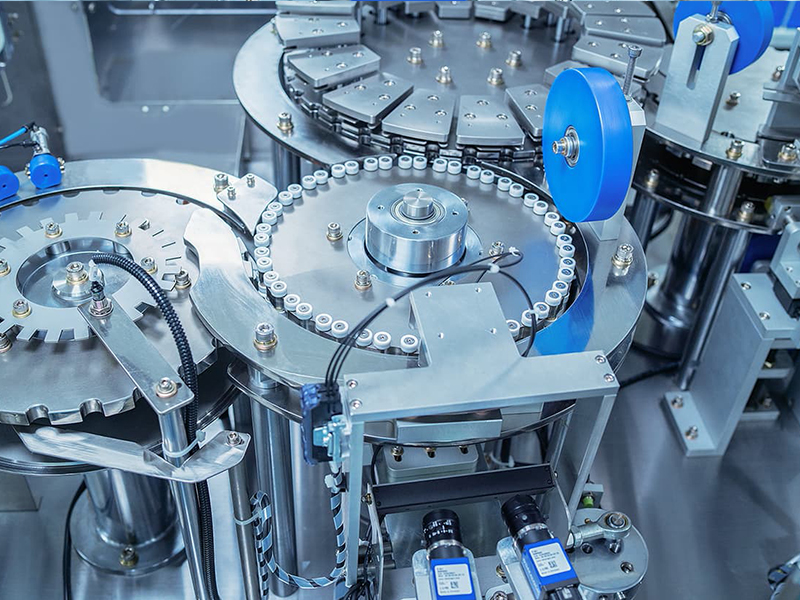

4. Intelligentization: Automation equipment widely uses Internet of Things (IoT), big data and artificial intelligence (AI) technologies to achieve intelligent monitoring, data analysis and production optimization. Intelligent equipment can monitor various data in the production process in real time, record and analyze it, and promote intelligent management of enterprises.

5. Safety: Automation equipment is equipped with a variety of safety protection devices and systems, which can effectively reduce safety hazards in the production process and ensure the safety of operators. Automated operations reduce workers’ labor intensity and improve the safety and comfort of the working environment.

The main advantages of automation equipment

1. Improve production efficiency: Automated equipment has greatly improved production efficiency by reducing manual operations and optimizing the production process. Traditional manual production methods often require a lot of manual operations and frequent adjustments, while automated equipment can achieve continuous, high-speed production operations, reducing waiting time and downtime during the production process. For example, in the automobile manufacturing industry, automated equipment can complete the assembly of a large number of parts in a short time, greatly improving production speed and efficiency.

2. Improve product quality: Automation equipment is equipped with advanced sensors and control systems, which can monitor and control every production link in real time to ensure the consistency and stability of product quality. The high-precision operation of automated equipment reduces human errors and improves product accuracy and consistency. For example, in electronic product manufacturing, automated equipment can precisely control every soldering point and assembly link to ensure that every product reaches high quality standards.

3. Reduce production costs: Although the initial investment in automation equipment is relatively high, its efficient production capacity and low operating costs significantly reduce overall production costs. Automated equipment reduces dependence on labor, lowering labor costs and management costs. In addition, efficient production and precise control reduce the waste of raw materials and improve resource utilization. For example, in the food processing industry, automated equipment can accurately control the usage of raw materials, reducing the waste of raw materials and reducing production costs.

4. Enhance production flexibility: Modern automation equipment is highly flexible and can quickly adjust and switch according to different product needs. By replacing molds, adjusting parameters and upgrading software, automation equipment can adapt to product production needs of various specifications and shapes, meet the diversified needs of the market, and improve the market competitiveness of enterprises. For example, in the home appliance manufacturing industry, automated equipment can quickly adjust production parameters to meet the production needs of different types of home appliances.

5. Improve operational safety: The use of automated equipment reduces the frequency and intensity of manual operations and reduces the risk of safety accidents that may occur during the operation. Equipment is usually equipped with a variety of safety protection devices, such as safety doors, emergency stop buttons, photoelectric protection, etc., to ensure the safety of operators. In addition, automated operations reduce workers’ labor intensity and improve the safety and comfort of the working environment. For example, in chemical production, automated equipment can automatically handle and operate hazardous chemicals, reducing the risk of workers being directly exposed to dangerous goods.

6. Data monitoring and management: Automation equipment is equipped with advanced data collection and monitoring systems, which can monitor various data in the production process in real time, and record and analyze it. Enterprises can use these data to optimize and improve the production process and improve production efficiency and product quality. At the same time, data accumulation and analysis can also provide scientific basis for enterprises' production decisions and promote intelligent management of enterprises. For example, in the pharmaceutical industry, automated equipment can record the production data of each batch of drugs in real time, facilitate tracking and management, and improve the transparency and safety of drug production.

The development direction of automation equipment

1. Intelligence and digitalization: With the development of Industry 4.0, automation equipment will become more intelligent and digital. By introducing Internet of Things (IoT) and artificial intelligence (AI) technologies, equipment can achieve intelligent monitoring, predictive maintenance and production optimization, improving the intelligence level of equipment.

2. Modular design: Future automation equipment will be more modular and can be quickly adjusted and upgraded according to different production needs, improving equipment flexibility and production efficiency.

3. Environmental protection and energy saving: Environmental protection and energy saving will become important directions for the development of automation equipment in the future. Equipment will use more environmentally friendly materials and energy-saving technologies to reduce energy consumption and environmental pollution and promote the development of green manufacturing.

4. High precision and high speed: As the market's demand for high quality and high efficiency continues to increase, automation equipment will develop towards higher precision and higher speed, improving production efficiency and product quality.

5. Human-machine collaboration and safety: Human-machine collaborative robots will be widely used in automation equipment. Combined with artificial intelligence and sensing technology, human-machine collaboration equipment will enable more efficient and safer production operations, improving production efficiency and the safety of the working environment.

With its high efficiency, accuracy and stability, automation equipment is leading the development trend of modern manufacturing industry. It has significant advantages in improving production efficiency, improving product quality, reducing production costs, enhancing production flexibility, improving operational safety and data monitoring and management, and has become an important means for enterprises to enhance market competitiveness. With the continuous advancement of technologies such as intelligence, digitization, modularization, environmental protection and human-machine collaboration, automation equipment will continue to develop, bringing greater economic benefits and market competitiveness to enterprises. In the future, automation equipment will continue to play an important role in promoting various industries to move towards efficient, intelligent and sustainable development.