Release Date:2025-03-14 15:25:11 Popularity:

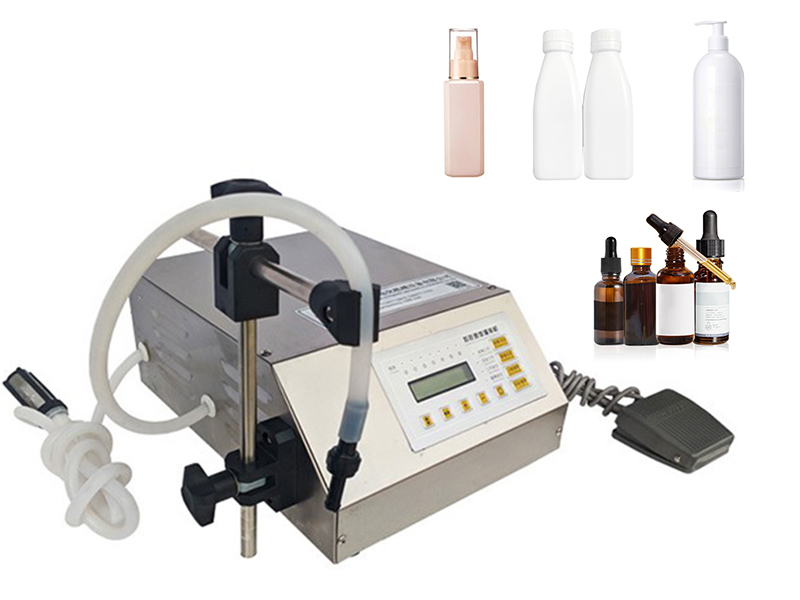

In modern industrial production, filling equipment is an indispensable and important equipment for food, pharmaceutical, chemical, daily chemical and other industries. According to the different degree of automation, filling machine can be divided into manual filling machine, semi-automatic filling machine and automatic filling machine. Among them, semi-automatic filling machine because of its cost-effective, easy to operate, adaptable, become the ideal choice for small and medium-sized enterprises and some special production needs of enterprises.

First, the working principle of semi-automatic filling machine

Semi-automatic filling machine is mainly composed of storage tanks, filling systems, measuring devices, control panels, operating platforms and other components, its working principle is as follows:

1. Material conveying: the material is conveyed to the filling system through hopper or pipeline, which can adopt gravity flow, pneumatic pressure conveying or pump pressure conveying method.

2. Measuring control: different measuring methods such as piston type, screw type, weighing type or flow meter are adopted to ensure accurate and consistent filling quantity each time.

3. Manual assisted operation: the operator is required to manually place the bottle or container and start the filling button to complete the filling of liquid, paste or powder.

4. Automatic completion of filling: the equipment automatically completes the filling of materials according to the set dosage, and can be equipped with anti-dripping devices to ensure production hygiene.

5. Manual take out the finished product: after the filling is completed, the workers take out the finished product, and can carry out the subsequent sealing, labeling, packaging and other processes.

Second, the core advantages of semi-automatic filling machine

1. Cost-effective: compared with the automatic filling machine, semi-automatic filling machine equipment costs are lower, suitable for small and medium-sized enterprises with limited budget.

2. Easy to operate, low maintenance costs: the equipment adopts humanized design, intuitive user interface, even if non-professionals can be quickly started after simple training.

3. Strong adaptability: it can be applied to a variety of materials such as liquid, paste, powder, granules, etc., and support different specifications and materials of bottles or packaging containers.

4. High filling precision: adopting precise measuring system to ensure the same amount of filling for each bottle, reducing waste and improving product quality.

5. Small footprint: compact equipment structure, small footprint, suitable for small factories, laboratories, customized production and other scenarios.

6. Applicable to a variety of production needs: can be used for small batch production, can also be used as a fully automatic production line of the pre-test equipment or standby equipment.

Third, semi-automatic filling machine application areas

1. Food and beverage industry: it is suitable for filling liquid or semi-fluid food such as juice, milk, honey, edible oil, sauces, seasonings and so on.

2. Pharmaceutical industry: it can be used for accurate quantitative filling of medicine, alcohol, disinfectant, oral liquid, syrup and other drugs.

3. Daily chemical industry: It is suitable for packaging of daily chemical products such as shampoo, shower gel, hand soap, skin care products, lotion, cream and so on.

4. Chemical industry: suitable for safe filling of lubricant, paint, cleaner, insecticide, glue and other chemicals.

5. Agriculture and pesticide industry: can be used for pesticides, fertilizers, feed additives and other fluid materials packaging.

Fourth, the future development trend of semi-automatic filling machine

1. Intelligent and digital upgrading: the future of semi-automatic filling machine will be combined with PLC control system, touch screen operation, intelligent sensors and other technologies to improve the degree of operational intelligence.

2. Improve filling accuracy and efficiency: the use of more advanced servo motor control, photoelectric sensing technology to further improve filling accuracy and speed, reduce waste.

3. Modular and multi-functional design: the future semi-automatic filling machine will have modular expansion function, users can replace different filling head according to demand, to achieve multi-purpose machine.

4. Upgrade of environmental protection and hygiene standards: food-grade stainless steel material, in line with GMP, HACCP, ISO and other international quality certification to ensure product safety and hygiene.

5. Compatible with automatic production line: part of the semi-automatic filling machine can be used as a complementary equipment for automatic production line, flexible to adapt to different production needs.

Semi-automatic filling machine with its high efficiency, precision, cost-controllable features, widely used in food, pharmaceutical, daily chemical, chemical and other industries, is the ideal choice for small and medium-sized enterprises and special production needs of enterprises. With the development trend of intelligence, precision and environmental protection, semi-automatic filling machine will usher in more technological upgrades in the future to provide better filling solutions for industrial production. For enterprises, choose a suitable semi-automatic filling machine, not only to improve production efficiency, but also to ensure stable product quality, to create greater value for enterprise development.