The Automatic Pipette Leak Detector is a high-precision testing solution designed for the reliable detection of leaks in laboratory pipettes. With advanced sensor technology and automated handling,

The Automatic Pipette Leak Detector is a high-precision testing solution designed for the reliable detection of leaks in laboratory pipettes. With advanced sensor technology and automated handling, this equipment ensures every pipette undergoes strict quality control before reaching the market. It is widely used in medical consumables manufacturing, biotech research, and laboratory equipment production.

This leak detection system features fully automated loading, testing, and sorting, eliminating human error and significantly improving inspection efficiency. The Automatic Pipette Leak Detector can accurately identify micro-leakage, ensuring compliance with international quality standards while reducing material waste and production costs.

Engineered for high-speed operation, flexibility, and stability, the system can be customized to integrate seamlessly with automatic pipette production lines. With its user-friendly interface and intelligent data recording, manufacturers gain real-time monitoring and traceability for enhanced quality assurance.

Choosing the Automatic Pipette Leak Detector means upgrading to a smarter, more efficient, and more reliable solution for pipette quality testing. It is the ideal choice for companies seeking to achieve large-scale, automated, and precision-driven production.

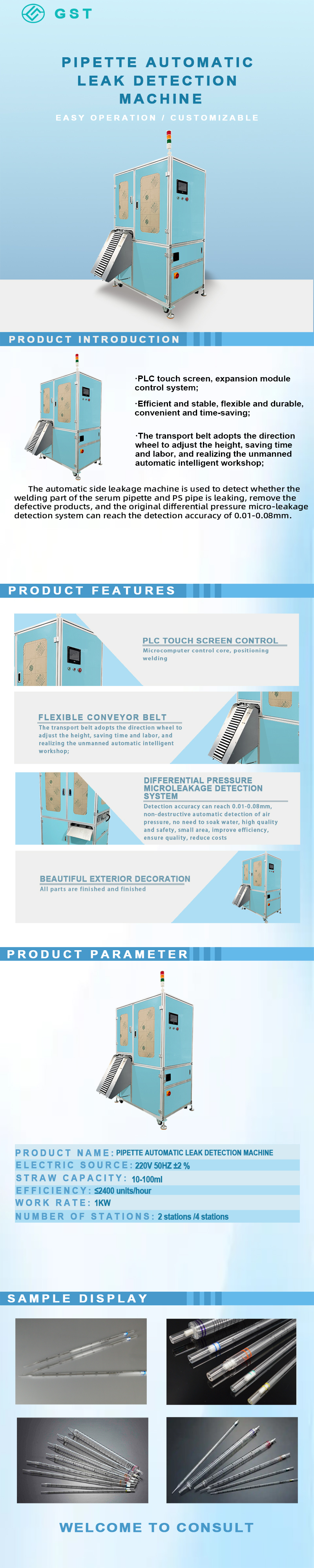

Equipment Function:

Automatic side leakage machine is used to detect whether serum pipettes and PS tubes are leaking at the welding part and take out the defective products.

Equipment features:

Pipette automatic leakage detection, automatic removal of defective products.

Technical Parameters:

Model: GST-YYG104A

Pipette capacity: 10-100ml