The freezing tube automatic production line is an intelligent production facility designed specifically for medical consumables. It is widely used in biological laboratories, hospitals, testing reag

The freezing tube automatic production line is an intelligent production facility designed specifically for medical consumables. It is widely used in biological laboratories, hospitals, testing reagent companies, and in vitro diagnostic reagent manufacturers.

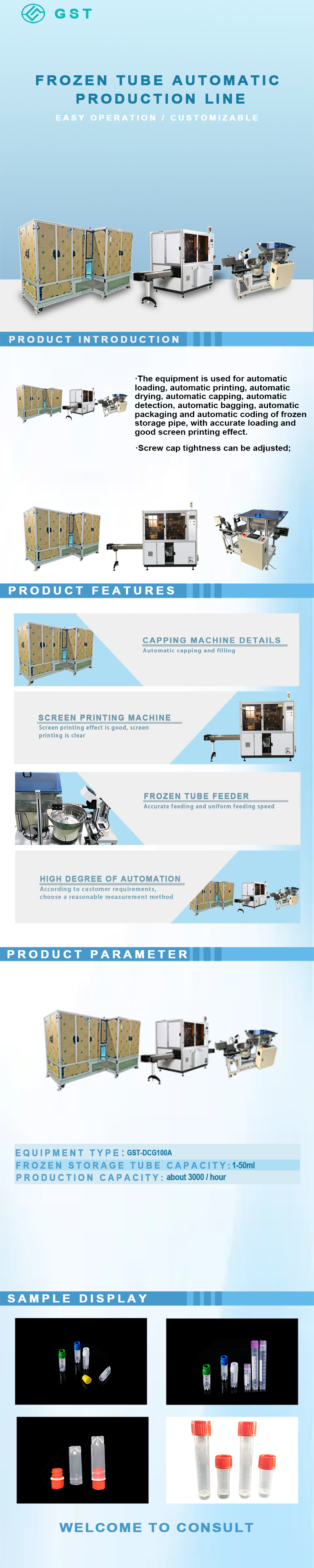

This line integrates multiple processes, including automatic loading, tube assembly, capping, sealing, testing, labeling, and packaging, enabling fully automated production of freezing tubes from raw materials to finished product, significantly improving production efficiency and product consistency.

The equipment utilizes advanced servo drives and visual inspection systems to ensure high precision and stability in freezing tube assembly. It can also be flexibly customized to meet customer needs and accommodate freezing tubes of varying specifications.

The entire production process is sealed, eliminating the risk of contamination from human contact and complying with GMP and ISO medical device production standards.

This equipment is used for automatic loading, automatic printing, automatic drying, automatic capping, automatic inspection, automatic bagging, automatic encapsulation and automatic coding of cryopreservation tubes.

Equipment features:

1) accurate loading of frozen storage tube automatic production line;

2) good silk screen printing effect;

3) adjustable tightness of capping;

4) adjustable packaging quantity.

Technical parameters:

Equipment Model: GST-DCG100A

Freezing tube capacity: 1-50ml

sizes: 3600*8 800*1800mm

production capacities: <2880 Pcs/hour 15ml: 50 Pcs/bag50ml: 25 Pcs/bag

power (output): 3KW

Customized Support: Yes