The automatic two-color screen printer for pipettes is a high-precision printing machine designed specifically for the laboratory consumables industry. It is primarily used for two-color screen prin

The automatic two-color screen printer for pipettes is a high-precision printing machine designed specifically for the laboratory consumables industry. It is primarily used for two-color screen printing of graduations, logos, and brand information on the outer surfaces of disposable pipettes. Combining automation technology with screen printing techniques, this machine enables high-volume, continuous, and efficient printing of pipettes, significantly improving production quality and efficiency.

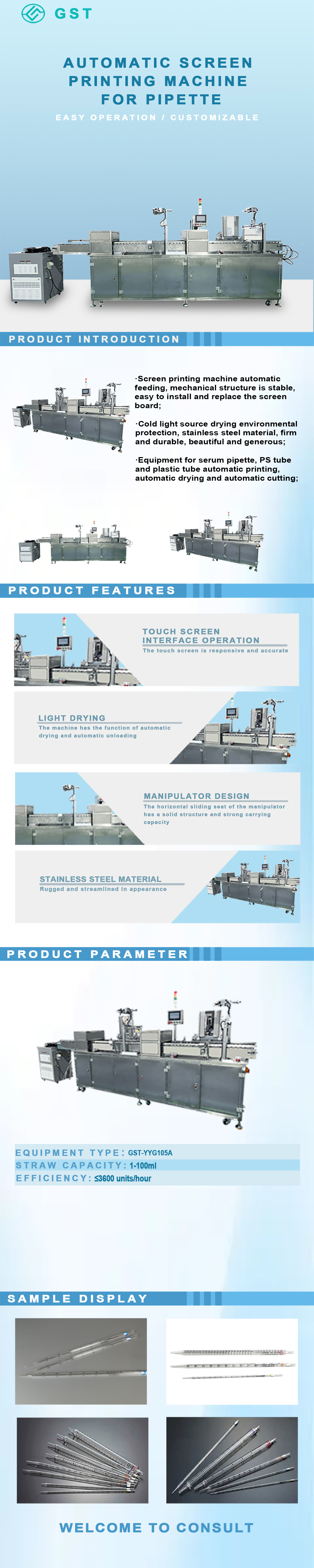

Equipment Features:

Two-color printing, one-shot completion: The machine simultaneously prints two colors on the surface of pipettes, eliminating the need for secondary processes. The printing is precise and ensures clear and consistent graduations and logos.

High-precision positioning: Automatic loading and precise positioning ensure stability and repeatability of each pipette during the printing process.

Automated operation: The entire process, including loading, positioning, printing, drying, and receiving, is fully automated, significantly reducing manual intervention and improving production efficiency.

Intelligent operation: Equipped with PLC control and a touchscreen human-machine interface, parameters can be freely configured and stored, making operation simple and allowing for quick switching between different pipette sizes.

Strong Compatibility: Compatible with pipettes of varying sizes and materials, it supports customized designs and can be integrated with other automated equipment (such as chip blowers, cartoners, and packaging machines) to create a complete production line.

Stable and Durable: Core components are made of high-quality materials, offering wear resistance and durability, enabling long-term continuous production operations.

The equipment carries out automatic printing, automatic drying and automatic discharging of serum pipettes, PS tubes and plastic tubes.

Equipment features:

1) Automatic loading of screen printing machine; 2) Stable mechanical structure; 3) Easy to install and replace the stencil; 4) Cold light drying and environmental protection; 5) Stainless steel material, firm and durable, beautiful and generous.

Technical Parameters:

Equipment Model: GST-YYG105A

Pipette capacity: 1-100ml

sizes: L340*W112*H175 CM

production capacities: 3600pcs/hour

power (output): 220-240VAC, 50/60Hz

Customized Support: Yes