The automatic liquid quantitative filling machine is a highly efficient, intelligent device designed specifically for filling liquid products in the food, beverage, daily chemical, pharmaceutical, a

The automatic liquid quantitative filling machine is a highly efficient, intelligent device designed specifically for filling liquid products in the food, beverage, daily chemical, pharmaceutical, and chemical industries. Using an advanced metering control system, it achieves precise filling and sealing of various liquid materials (such as beverages, soy sauce, liquid medicines, reagents, and chemical solutions). Its fast speed, high precision, and high degree of automation make it an indispensable core piece of equipment in modern production lines.

Key Functions and Features:

High-Precision Quantitative Filling: Utilizes a variety of precision metering methods, including flow meters, piston metering, and servo pumps, ensuring consistent filling volume for each bottle with minimal error.

Multi-Specification Compatibility: Quickly adjusts the number of filling heads, filling volume, and filling speed to accommodate different bottle sizes and production requirements.

High Automation: Integrates automatic bottle unscrambling, filling, capping, sealing, and coding, minimizing manual intervention.

Hygienic and Safe Materials: Material contact parts are constructed of food-grade stainless steel, complying with GMP and ISO standards, ensuring corrosion resistance and easy cleaning.

Intelligent Operating System: A PLC and touchscreen human-machine interface enables intuitive parameter settings, real-time display of operating status, and support for multi-station data management.

High Scalability: Can be integrated with labeling, capping, and case packing equipment to achieve complete line automation based on production needs.

Applications:

Food and Beverage Industry: Filling of beverages, milk, sauces, condiments, cooking oil, etc.;

Pharmaceutical and Health Products Industry: Filling of oral liquids, medicines, disinfectants, etc.;

Daily Chemical Industry: Packaging of liquids such as detergents, skincare products, hand sanitizers, and disinfectants;

Chemical Industry: Filling of lubricants, chemical reagents, etc.

Use Benefits:

Improve Production Efficiency: Continuous high-speed filling significantly reduces labor costs;

Stabilize Product Quality: Accurate metering and leak-free filling enhance brand image;

Intelligent Upgrade: Can be integrated with upstream and downstream processes to create a fully automated production line.

With its high precision, high efficiency, and high stability, automatic liquid dosing filling machines have become an ideal choice for companies to achieve large-scale, standardized, and intelligent production of liquid products, providing strong equipment support in the fiercely competitive market.

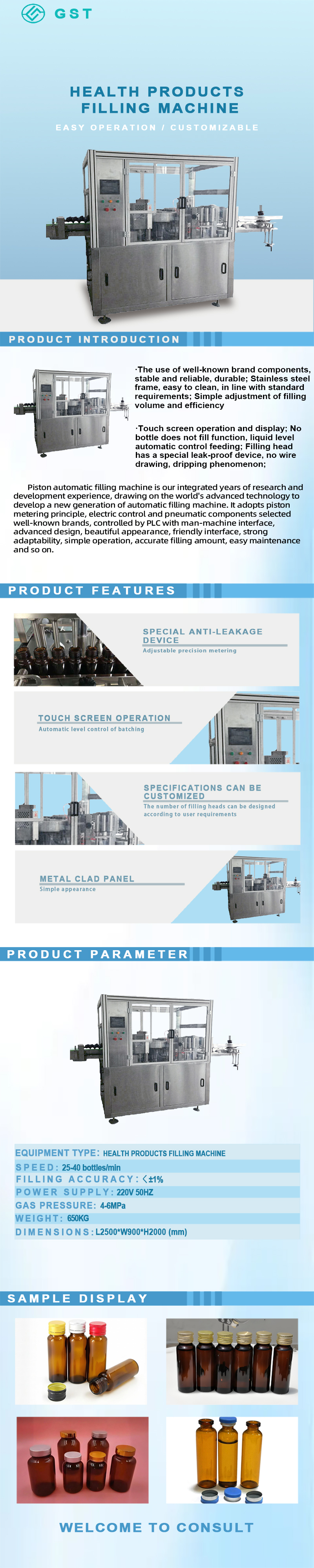

Product features:

1)Adopting famous brand components, stable, reliable and durable;.

2)Adopting stainless steel frame, easy to clean and meet the standard requirements;.

3)Simple adjustment of filling volume and efficiency, touch screen operation and display;.

4)No bottle not filling function, liquid level automatic control of filling.

5)Filling head has special anti-leakage device, no pulling and dripping phenomenon.

6)Different number of filling heads can be designed according to user requirements.

Technical parameters:

1)model number: GST-SWYP005A

2)Filling capacity: 25-250ml,50-500ml,150-1000ml,500-2500ml(different specifications can be ordered).

3) Canning efficiency: 25-40 bottles/minute (6 heads in the range of 50-500ml).

4)Canning precision: <±1%.

5)Power supply: 220V 50HZ.

6)Air pressure: 4-6MPa.

7)Overall dimension: 2500*900*2000mm.

8)Quality: 650KG.

9)Customized Support: Yes