The semi-automatic paste filling machine is a highly efficient, quantitative filling machine designed for various high-viscosity pastes. It is widely used in the food, daily chemical, pharmaceutical

The semi-automatic paste filling machine is a highly efficient, quantitative filling machine designed for various high-viscosity pastes. It is widely used in the food, daily chemical, pharmaceutical, cosmetics, and chemical industries. Combining compact design, easy operation, and high precision, it is an ideal choice for small and medium-sized enterprises or high-variety, small-batch production lines.

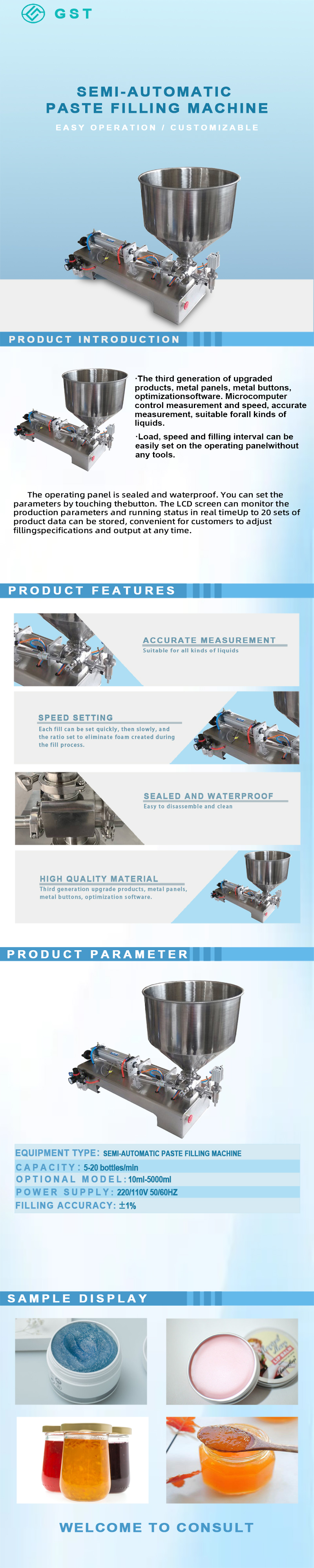

Features:

Precise and quantitative: Utilizing a high-quality pneumatic control and quantitative filling system, it enables precise filling of high-viscosity materials such as pastes, gels, and lotions, reducing waste and improving production efficiency.

Easy Operation: The user-friendly touch panel or foot switch allows for simple and intuitive operation, reducing training costs.

Safe and hygienic materials: All material-contacting parts are constructed of 304 or 316L stainless steel, meeting the hygienic standards of food and pharmaceutical production and easily disassembled and cleaned.

Versatile: The filling volume, filling nozzle, and hopper capacity can be customized to meet the filling needs of materials of varying specifications and viscosities.

High Cost-Effectiveness: Semi-automatic paste filling machines feature a simple structure and easy maintenance, making them ideal for businesses seeking a cost-effective and quick start-up.

Applications:

Food Industry: Filling jams, honey, peanut butter, chili sauce, etc.

Cosmetics Industry: Filling creams, toothpaste, skin care creams, conditioners, etc.

Pharmaceutical Industry: Filling ointments, gels, disinfectant pastes, etc.

Chemical Industry: Filling greases, glue pastes, cleaning pastes, etc.

Semi-automatic paste filling machines offer low investment costs, flexible operation, easy maintenance, and high precision, making them particularly suitable for start-ups and factories requiring flexible production. They are an ideal choice for businesses seeking to increase production capacity while maintaining quality.

For those requiring higher levels of automation and complementary packaging solutions, these machines can be paired with fully automatic filling, capping, and labeling lines to achieve comprehensive improvements in both production capacity and efficiency.

Technical parameters:

model number: GST-SWYP003A

sizes: 1600*300*1000mm

Optional models: 10ml -5000ml ;

Power supply: 220/110V 50/60HZ.

Air pressure: 0.4-0.6MPa.

Filling speed: 5-20 bottles/minute (the machine power for the gas source, can meet the large and small enterprises to use);.

Filling precision: ≤±1%.

Customized Support: Yes