The automatic paste and liquid filling machine is a modern filling device that integrates high-precision metering, automated operation, and versatile adaptability. It is widely used for filling past

The automatic paste and liquid filling machine is a modern filling device that integrates high-precision metering, automated operation, and versatile adaptability. It is widely used for filling pastes and liquid materials in the food, daily chemical, pharmaceutical, and chemical industries. It features automatic loading, quantitative filling, no-bottle-stop filling, and automatic counting, helping companies improve production efficiency, reduce labor costs, and ensure consistent product quality.

High-Precision Metering: Utilizing advanced metering pumps or servo control systems, it ensures accurate filling volume per bottle or bag, with an error of less than ±1%.

Wide Applicability: It can fill both pastes (such as toothpaste, creams, sauces, glues, etc.) and liquids (such as beverages, liquid medicines, and detergents), meeting diverse production needs with a single machine.

Intelligent Control: Equipped with a PLC programmable controller and a touchscreen interface, it allows for convenient parameter adjustment, including one-touch setting of filling speed and volume.

Safe and Hygienic Design: Constructed of stainless steel, it complies with GMP standards for food and pharmaceutical production and is easy to disassemble and clean.

Multiple leak prevention systems: Utilizing anti-drip devices and a special valve structure, the filling process is clean and tidy, reducing waste.

Modular design: Customizable based on customer production volume and packaging specifications, supporting expanded functions such as multi-head filling, automatic capping, and sealing.

Stable and durable: Key components are sourced from internationally renowned brands, ensuring stable performance even after long periods of continuous operation.

Labor savings: Fully automated production can replace multiple workers, reducing labor costs.

Food industry: Sauces, honey, jams, beverages, dressings, etc.

Pharmaceutical industry: Ointments, oral liquids, nutritional solutions, etc.

Daily chemical industry: Shampoo, shower gel, hand soap, face cream, etc.

Chemical industry: Glue, lubricant, disinfectant, etc.

Automatic paste and liquid filling machines, with their high efficiency, precision, intelligence, and safety, have become the preferred equipment for modern enterprises to improve production capacity and product quality. Whether small or medium-sized enterprises or large production lines, adopting this type of equipment can significantly improve production automation and market competitiveness.

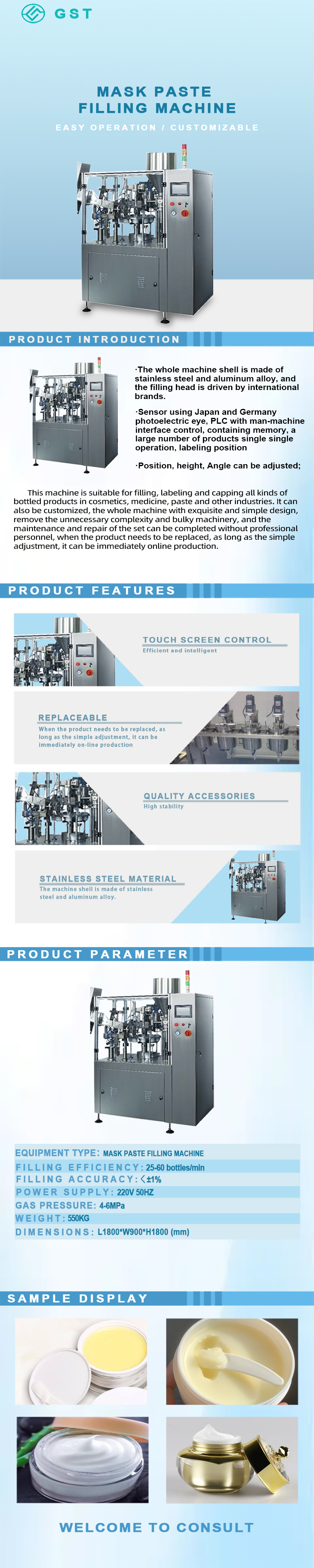

Product features:

1) The whole machine shell is made of stainless steel and aluminum alloy;

2) The filling head is driven by international brands;

3) The sensor uses photoelectric eyes from Japan and Germany;

4) PLC cooperates with human-machine interface control and contains memory;

5) Single machine and single-person operation for large-volume products;

6) The labeling position, height and angle can be adjusted.

Technical parameters:

1) model number: GST-SWYP007A

2) Filling efficiency: 25-60 bottles/minute;

3)Filling accuracy: <±1%;

4) Power supply: 220V 50HZ;

5) Air pressure: 4-6MPa;

6) Dimensions: 1800*900*1800mm;

7) Mass: 550KG.

8) Customized Support: Yes