The automatic two-color screen printer for pipettes is a high-precision, automated screen printing machine designed specifically for the laboratory consumables industry. Utilizing an intelligent con

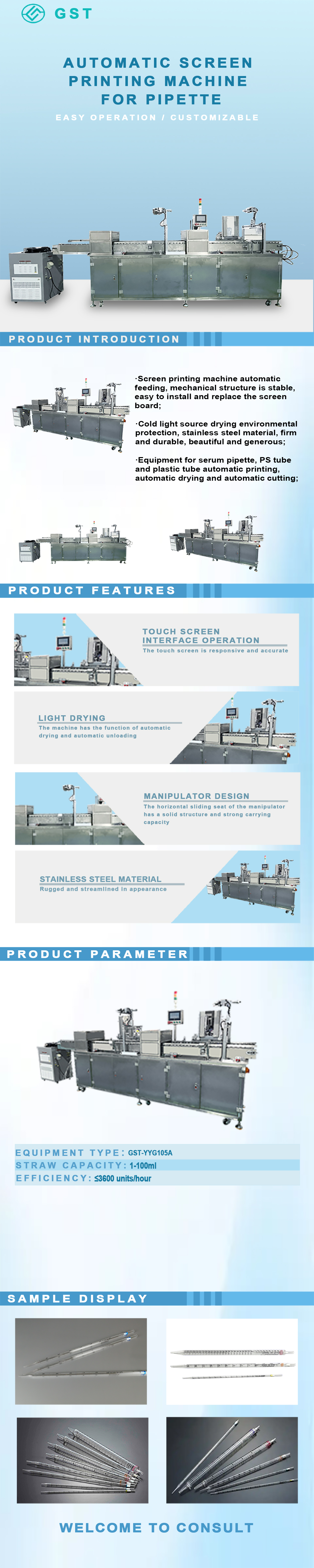

The automatic two-color screen printer for pipettes is a high-precision, automated screen printing machine designed specifically for the laboratory consumables industry. Utilizing an intelligent control system and high-precision servo drive technology, it performs the entire process of automatic loading, precise positioning, two-color printing, and automatic unloading for various plastic pipette sizes (such as 1ml, 5ml, and 10ml), significantly improving production efficiency and print quality.

The machine features a dual-station simultaneous printing structure with independent control of each color, allowing flexible adjustment of printing position and color alignment based on product requirements, achieving ghost-free, high-precision printing. Combined with a vision positioning system and automatic deflection correction mechanism, it ensures consistent, beautiful, and clear printing on each pipette, meeting the high-standard production requirements of medical consumables.

The GST automatic two-color screen printer for pipettes adopts a modular design, compatible with a wide range of product sizes, allowing for quick line changeovers and easy maintenance. Constructed primarily of stainless steel and aluminum alloy, the machine complies with GMP cleanroom standards, is corrosion-resistant, and easy to clean. The intelligent human-machine interface (HMI) is easy to operate and provides real-time monitoring of printing speed, ink level, and operating status. It also features abnormality alarms and automatic shutdown protection, ensuring safe and stable equipment operation.

Compared to traditional manual screen printing or single-color printing equipment, the GST automatic two-color screen printer can save approximately 70% of labor costs while achieving high-speed, high-precision, and highly consistent print output. It is an ideal automated screen printing solution for industries such as laboratory consumables, medical testing, and in vitro diagnostics (IVD).

As a professional manufacturer of customized automated production equipment, GST offers complete integrated line solutions tailored to customer needs. From automated pipette loading, screen printing, drying, testing, and assembly, GST enables unmanned automated production, helping companies build smart manufacturing factories and enhance brand competitiveness.

Technical Parameters:

Equipment Model: GST-YYG105A

Pipette capacity: 1-100ml

sizes: L340*W112*H175 CM

production capacities: 3600pcs/hour

power (output): 220-240VAC, 50/60Hz

Customized Support: Yes