The automated centrifuge tube production line is a complete intelligent equipment system designed for manufacturers of laboratory consumables. It covers multiple processes including automatic feedin

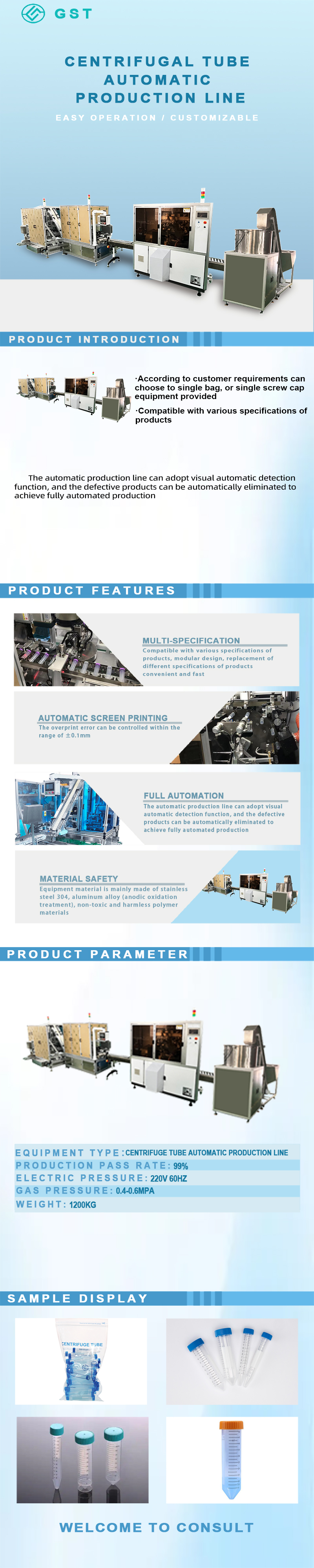

The automated centrifuge tube production line is a complete intelligent equipment system designed for manufacturers of laboratory consumables. It covers multiple processes including automatic feeding, screen printing of scales, automatic inspection, bagging and sealing, and finished product packaging, achieving continuous and unmanned production of centrifuge tubes from raw materials to finished products.

The production line utilizes servo control, visual inspection, precision mechanical structures, and a stable automatic transmission system to ensure that each centrifuge tube has consistent dimensions, clear markings, and is clean and flawless. The system supports rapid switching between multiple centrifuge tube sizes, such as 1.5ml, 5ml, 15ml, and 50ml, and can be modularly expanded and customized according to customer process requirements.

Compared to traditional manual operation, this intelligent production line can significantly increase production capacity, reduce defect rates, and lower labor costs, making it the preferred automated solution for achieving large-scale, standardized, and high-quality manufacturing in the laboratory consumables industry.

Technical parameters:

Equipment Model: GST-LXG100A

Centrifuge tube capacity: 15-50ml

Sizes: L8800*W1800*H1800mm

Production Capacities: 500pcs/min

Power (Output): 3KW

Customized Support: Yes