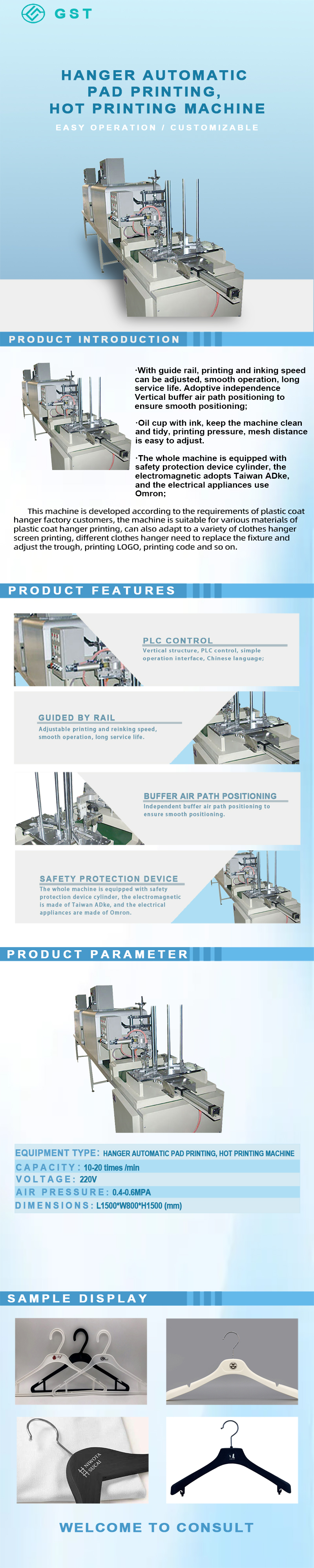

This automatic hanger pad printing machine is specifically designed for surface printing of logos, patterns, and text on metal, plastic, and flocked hangers, achieving automated, precise printing fr

This automatic hanger pad printing machine is specifically designed for surface printing of logos, patterns, and text on metal, plastic, and flocked hangers, achieving automated, precise printing from multiple angles and in multiple colors. The equipment utilizes advanced pad printing technology and an intelligent vision positioning system to overcome the challenges of traditional printing methods on curved and irregularly shaped hanger surfaces, such as inaccurate color registration, low efficiency, and poor ink adhesion.

High-precision visual positioning: Equipped with a CCD vision alignment system, it automatically identifies the hanger's position and angle, achieving a printing accuracy of ±0.05mm, and supporting precise color registration on curved and irregularly shaped hanger surfaces.

Fully automatic multi-color printing: Configured with 1-6 automatic pad printing units, it supports multi-angle simultaneous printing with the pad heads, achieving a cycle time as fast as 6 seconds, and a daily production capacity of over 10,000 pieces.

Intelligent constant pressure and ink control: Utilizing a closed-loop pressure control system and automatic ink compensation device, it ensures stable printing pressure, uniform ink layer, clear patterns without smudging, and adhesion reaching 5B level (cross-cut test).

Flexible and rapid changeover: Modular fixture design adapts to various types of hangers, including U-shaped, trouser clips, and folding hangers; touchscreen parameter programming reduces changeover and adjustment time to within 10 minutes.

Technical parameters:

Model Number: GST-WJ008A

Sizes: L1500*W800*H1500mm

Voltage: 220V AC

Air pressure: 0.4-0.6MPA.

Work efficiency: 10-20 times / min,

Cylinders, solenoid valves are made of Taiwan Yadek, and electrical appliances are made of Omron.

Customized Support: Yes