The semi-automatic pipette tip loading and packaging machine is specifically designed for the auxiliary packaging of laboratory pipette tips (PCR tips, filter tips, etc.). It combines manual feeding

The semi-automatic pipette tip loading and packaging machine is specifically designed for the auxiliary packaging of laboratory pipette tips (PCR tips, filter tips, etc.). It combines manual feeding with automatic sorting, counting, stacking, and packaging. Through a modular mechanical structure and intelligent control system, the equipment significantly improves packaging efficiency while ensuring packaging accuracy, providing a cost-effective solution for small to medium-batch, multi-specification pipette tip packaging.

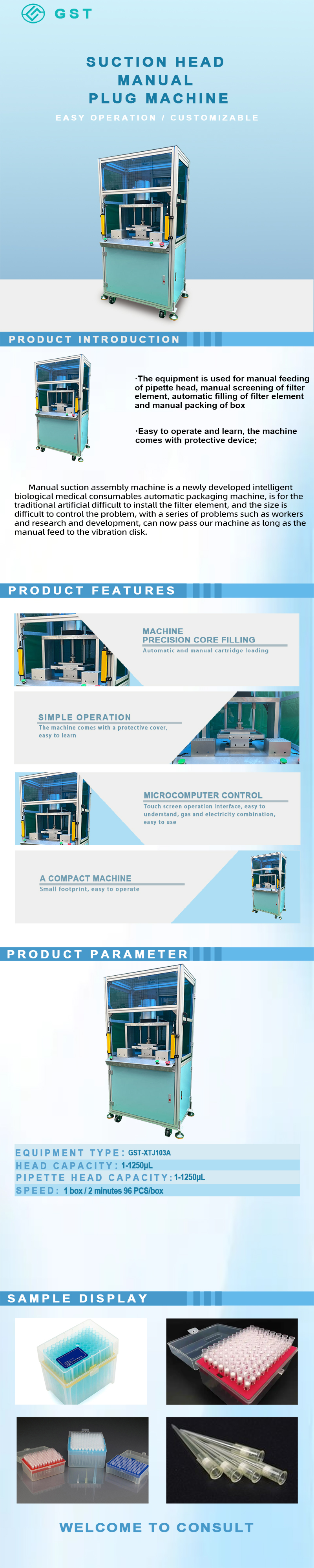

Human-Machine Collaborative Flexible Operation: Manual feeding of pipette tips, with the equipment automatically performing posture correction, alignment, stacking, counting, and packaging. Single box capacity (pipette tips) can reach 96 pieces, increasing operational efficiency by 200% compared to purely manual operation.

Highly Compatible Modular Design: Adaptable to various pipette tip specifications from 10μl to 1250μl, supporting quick changeover between types such as non-filtered, pre-filtered, and low-adsorption tips. Changeover time ≤ 8 minutes.

Precise Counting and Stacking: Equipped with a photoelectric counting system and servo stacking mechanism, the counting error is ≤ ±1 tip/box, and the stacking neatness reaches over 98%, effectively preventing pipette tip compression and deformation.

Compact, Stable, and Easy to Operate: Footprint ≤ 1.5㎡, with one-button start/stop and fault self-checking design, lowering the operating threshold; optional label printing and data recording functions are available.

Technical parameters:

Equipment Model: GST-XTJ103A

Sizes: 360*320*5250px

Tip capacity: 1-1250μL

Production Capacities: 1 box/minute 96 pcs/box

Power (Output): 1.5kw

Customized Support: Yes