1. The basic composition of the centrifuge tube automatic production line The centrifuge tube automatic production line is mainly composed of the following parts: raw material storage, raw material

1. The basic composition of the centrifuge tube automatic production line

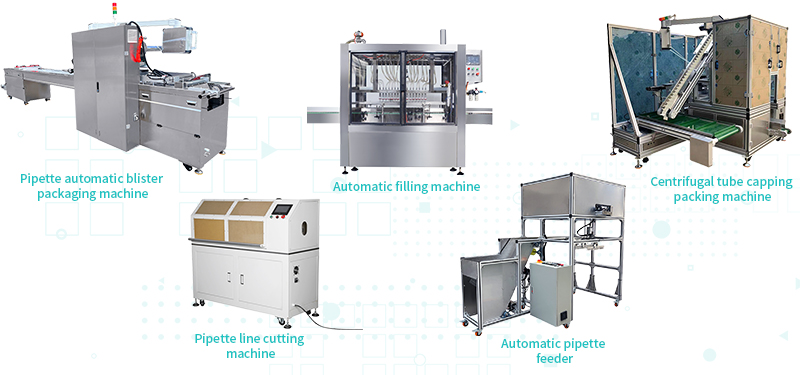

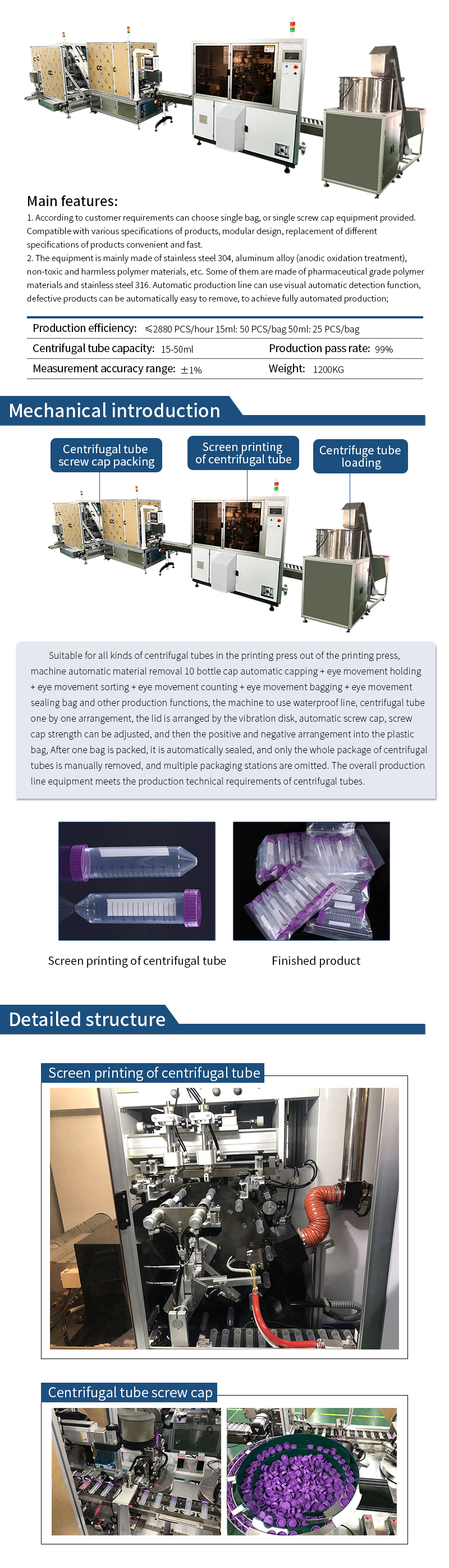

The centrifuge tube automatic production line is mainly composed of the following parts: raw material storage, raw material processing, centrifuge tube forming, heat treatment, quality inspection, finished product storage and other links. Each link is realized through automation equipment, sensors, control systems, etc., to ensure the stability of the production process and the consistency of the product.

2. The innovation of centrifuge tube automatic production line

Production process optimization: The automated production line fully optimizes the production process to realize the seamless connection of various production links and greatly improves production efficiency.

Application of intelligent control system: Through the intelligent control system, various parameters in the production process can be monitored in real time to ensure the stability of the production process and the controllability of product quality.

Combination of mechanization and automation: The automated production line fully integrates mechanization and automation technology, reduces manual intervention, and avoids production accidents and product quality problems caused by human factors.

3. Advantages of automatic centrifuge tube production line

Improve production efficiency: The automated production line has significantly improved production efficiency. Compared with the traditional production line, the output can be increased by more than 30%.

Reduce costs: reduce labor costs and equipment maintenance costs, so that the overall operating costs of the enterprise can be effectively controlled.

Improve product quality: Through automation equipment and intelligent control system, the consistency of products is guaranteed, and the product quality is significantly improved.

Flexible response to market demand: The automated production line has high production flexibility and can quickly adjust production plans to meet changes in market demand.