1. Working principle Plastic pipe ultrasonic welding machine mainly uses ultrasonic energy to weld plastic pipes. First, the ultrasonic generator generates high-frequency vibration and converts ele

1. Working principle

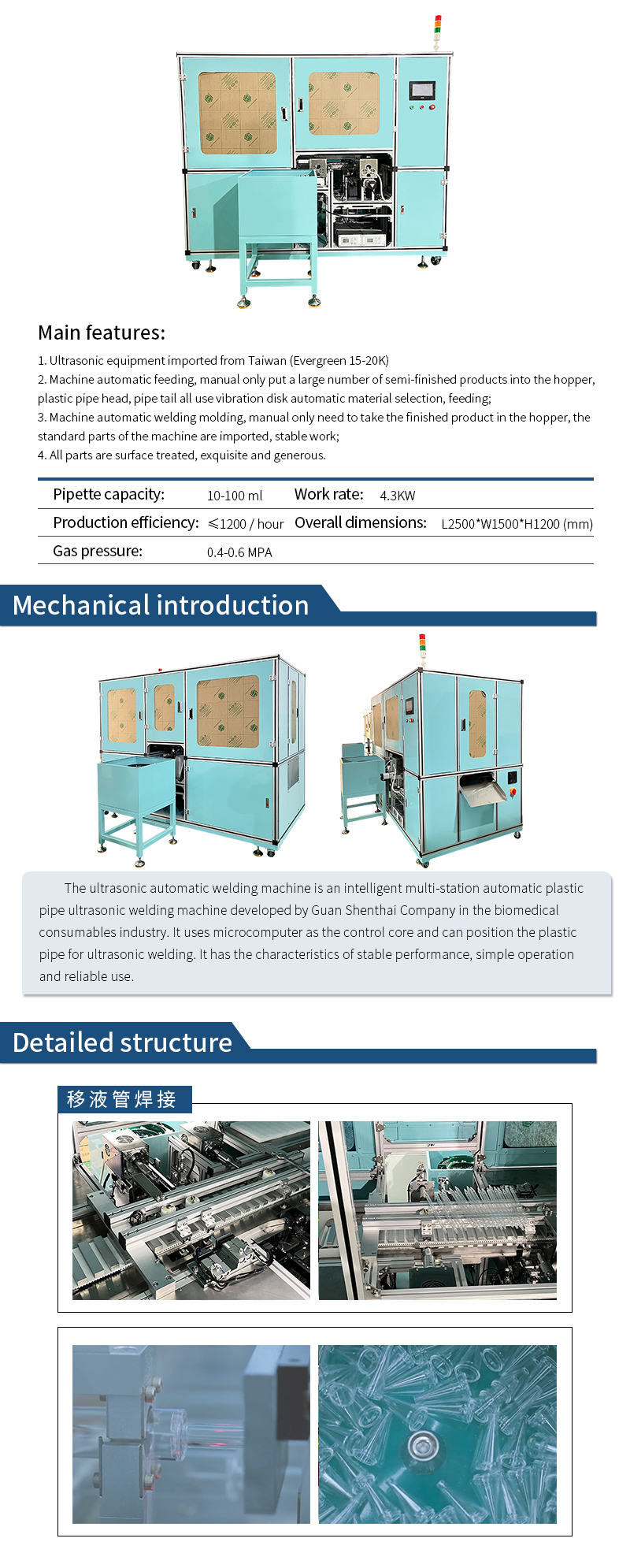

Plastic pipe ultrasonic welding machine mainly uses ultrasonic energy to weld plastic pipes. First, the ultrasonic generator generates high-frequency vibration and converts electrical energy into mechanical energy through the transducer. Then, the transducer transmits high-frequency vibration to the surface of the plastic pipe, causing the plastic pipe to generate frictional heat under the action of vibration energy. When the temperature reaches the melting point of the plastic pipe, the pipe walls melt and fuse together quickly. Finally, after the vibration stops, the plastic tube cools and solidifies, forming a strong welded joint.

2. Application fields

Automobile industry: In the automobile manufacturing industry, plastic pipes are widely used in cooling systems, hydraulic systems, and exhaust emission systems. Ultrasonic welding technology can quickly and stably connect plastic pipes, improve production efficiency and reduce costs.

Medical industry: In the medical field, plastic pipes are mainly used for infusion, blood transfusion, etc. Ultrasonic welding technology can realize fast and sterile connection of plastic pipes, improving the safety and reliability of medical equipment.

Electronics industry: In electronic products, plastic pipes are often used in cooling systems, fluid transportation, etc. Ultrasonic welding technology can accurately connect plastic pipes and improve the stability and safety of electronic products.

Construction industry: In the construction field, plastic pipes are widely used in water supply, drainage, HVAC, etc. Ultrasonic welding technology can connect plastic pipes efficiently and durablely, improving the quality and lifespan of buildings.

3. Advantages

Fast: The ultrasonic welding process can complete the welding of a large number of plastic pipes in a short time, improving production efficiency.

Efficient: Ultrasonic welding can fuse plastic pipes in a short time to form a strong joint and improve welding efficiency.

Stability: The ultrasonic welding process has a high degree of reliability and stability, which can ensure the stability of welding quality.

Non-destructive: Ultrasonic welding will not cause any damage to the surface of plastic pipes, improving the integrity and aesthetics of plastic pipes.

Environmental protection: Compared with traditional welding processes, ultrasonic welding processes produce less noise and pollution and are more environmentally friendly.

4. Precautions

Equipment maintenance: Regularly check various performance indicators of the ultrasonic welding machine, including power supply, transducer, amplitude modulator and other components to ensure that the equipment is working properly.

Parameter setting: According to different plastic pipe materials and thicknesses, the parameters of the ultrasonic welding machine should be reasonably set to achieve the best welding effect.

Safety protection: When operating ultrasonic welding machines, workers must wear professional protective glasses, gloves and other safety equipment to ensure safety.

Quality inspection: After welding is completed, quality inspection of the welded joints, such as appearance inspection, strength test, etc., should be carried out to ensure that the welding quality meets the requirements.