The automatic pipette chip blower is an auxiliary device designed specifically for removing waste chips from pipette cutting or grinding during pipette production. It is primarily used after pipette

The automatic pipette chip blower is an auxiliary device designed specifically for removing waste chips from pipette cutting or grinding during pipette production. It is primarily used after pipette cutting, stretching, and welding processes to remove plastic fragments, burrs, and particles remaining inside and outside the pipette through airflow or blasting, ensuring clean, impurity-free pipettes that meet the quality requirements of subsequent printing, assembly, and sealing processes.

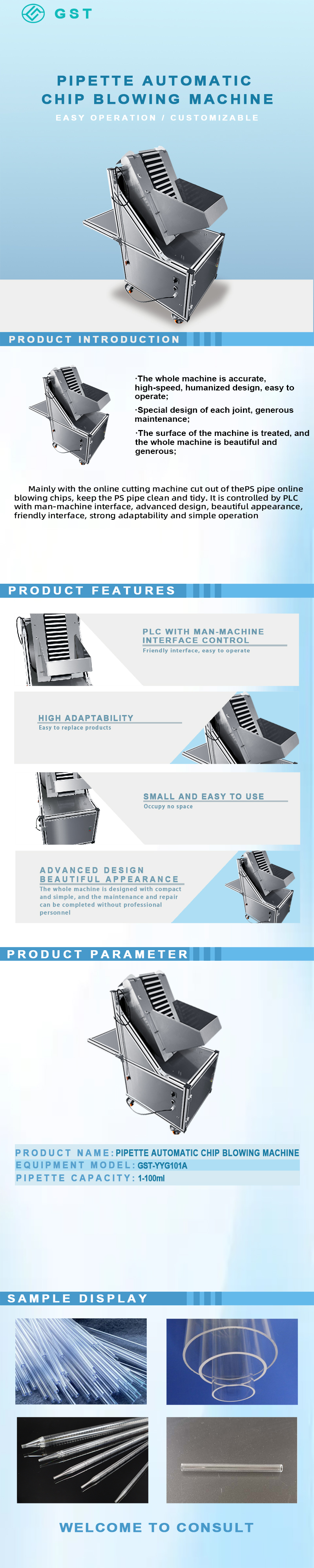

This device is typically used in conjunction with a pipette cutter or in-line production line to form an automated, integrated chip blower module. Key functions and features include:

Efficient chip removal: The device uses high-pressure airflow or compressed air to clean the interior and exterior of the pipette, quickly and thoroughly removing debris and ensuring product cleanliness.

Strong integration: It can be integrated with pipette cutters, stretchers, welders, and other equipment into an automated pipette production line, achieving coordinated control and synchronized operation.

Flexible specifications: It supports pipettes of varying lengths and diameters (e.g., pipettes ranging from 1–100 mL) by simply replacing the fixture or adjusting the nozzle position.

Simple Structure and Easy Maintenance: The built-in air duct is rationally designed for easy disassembly and cleaning; key components are treated with wear-resistant materials to extend their service life.

Automatic Control and Alarm Functions: Equipped with a PLC control system and touchscreen interface, it supports chip blowing parameter adjustment, air volume control, fault monitoring, and alarm notifications.

Low Noise and Energy-Saving Design: The fan and air supply system have been optimized to reduce noise interference, while also improving airflow utilization and lowering energy consumption.

Excellent Cleanability: The equipment surface and contact areas with pipettes are made of stainless steel, and the design is easy to clean, meeting cleanroom requirements.

In pipette production lines, residual debris can affect label application, printing accuracy, sealing, and even the reliability of subsequent testing. The introduction of an automatic pipette chip blower significantly reduces manual cleaning time, reduces defective product rates, and ensures stable production line cycles. It is an efficient, clean, and reliable automation auxiliary module.

Technical parameters:

model number: GST-YYG101A

Pipette capacity: 1-100ml

sizes: 1500*1000*1500mm

production capacities: 300pcs/min

power (output): 1.5kw

Customized Support: Yes