The automatic quantitative weighing and filling machine for pastes and liquids is an intelligent automated device designed specifically for high-viscosity materials such as pastes, creams, gels, and

The automatic quantitative weighing and filling machine for pastes and liquids is an intelligent automated device designed specifically for high-viscosity materials such as pastes, creams, gels, and pasty liquids. It integrates quantitative weighing, filling, sealing preparation (or coordination with downstream equipment), and inspection and rejection. It is suitable for production scenarios requiring "precision filling and consistency" in the cosmetics, daily chemical, pharmaceutical, and medical consumables industries.

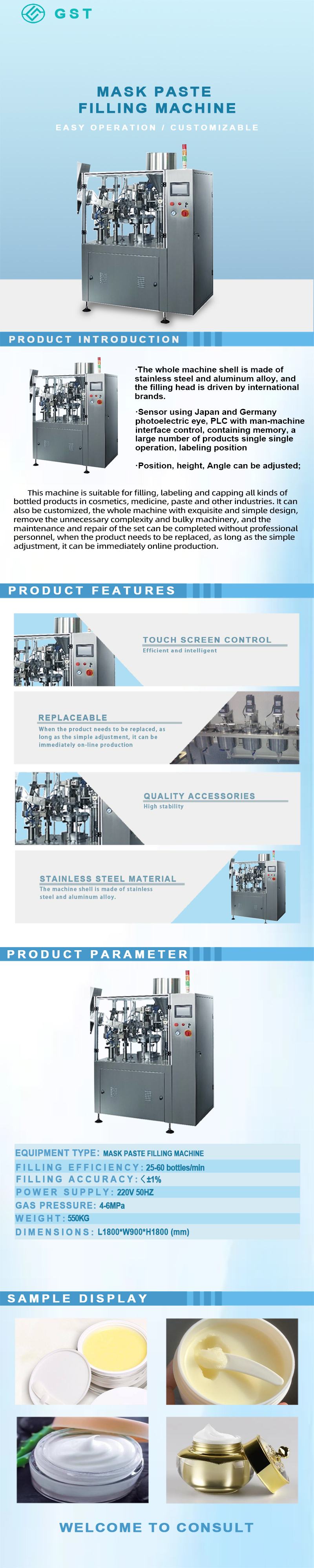

Core Functions and Structural Highlights:

Automatic Weighing and Quantifying Control: Equipped with a high-precision weighing system, the material is weighed and calibrated before filling, ensuring consistent volume and weight for each fill, with an error controllable to within ±1%.

Suitable for high-viscosity pastes and liquids: Utilizing a screw/plunger filling system combined with variable frequency/servo control, it features a "fast first, slow later" filling strategy, effectively preventing bubble formation, pumping lag, and overflow.

Automated processes significantly reduce manual intervention: From barrel feeding, lifting, conveying, weighing, filling, barrel changing, cleaning prompts, to the next cycle, one-touch process control ensures easy operation, making it suitable for medium- to large-scale continuous production.

Modularity and flexible switching: The machine's modular design allows for customization of the number of filling heads and weighing platforms based on production requirements. Multiple bag/bottle/tube sizes can be quickly switched to meet diverse product needs, small batches, and rapid mold changeovers.

Hygienic and easy-to-clean design: Material-contact parts are constructed of food-grade/pharmaceutical-grade stainless steel (e.g., 304 or 316L). Piping is quick to disassemble and easy to clean, meeting GMP/ISO production requirements.

Intelligent detection and exception handling: Equipped with post-filling weight deviation alarms, empty/mistaken bottle detection, and leak detection, the machine automatically pauses or rejects abnormal products, improving pass rates and reducing scrap rates.

Efficient Cycle Time and Increased Productivity: Compared to traditional manual or semi-automatic filling equipment, this machine achieves higher filling speeds and more stable cycle times. Combined with weight monitoring, it significantly improves overall production line efficiency.

Applicable Industries and Applications:

Cosmetics: Creams, eye creams, cleansing balms, hand creams, and other paste-based products.

Daily Chemicals: Facial cleansers, hair waxes, body lotions, and cream-based cleansers.

Pharmaceutical/Medical Consumables: Ointments, gels, paste dressings, and antigen/antibody paste reagents.

Other high-viscosity material applications: Honey sauces, honey pastes, and sauces are also suitable.

Technical parameters:

Model Number: GST-SWYP007A

Filling efficiency: 25-60 bottles/minute;

Filling accuracy: <±1%;

Power supply: 220V 50HZ;

Air pressure: 4-6MPa;

Dimensions: 1800*900*1800mm;

Mass: 550KG.

Customized Support: Yes