Release Date:2022-08-24 10:28:20 Popularity:

At present, with the development of industry, the demand for non-standard automation equipment is increasing; non-standard automation equipment has now become an important auxiliary equipment in many industries. When we need non-standard automation equipment, then the design and manufacturing steps of non-standard automation equipment What is it like?

1. Determine development projects and understand customer needs, including product quality requirements, equipment production efficiency requirements, and equipment working environment.

2. Analyze the product: understand the production process of the product, the size requirements and incoming materials in all aspects of the product; communicate with the customer the precautions in the production process of the product and the technical parameters of the place where the equipment is used.

3. Drafting a plan: The engineering personnel discuss and analyze the equipment plan. The plan includes: equipment schematic diagram (overall schematic diagram, partial schematic diagram), brief introduction of each part of the organization, action description, and equipment technical parameters.

4. Scheme review: The review team is composed of engineering personnel to review the scheme. The review contents include: equipment feasibility assessment, equipment cost assessment, equipment production efficiency assessment, and structural feasibility assessment of each part.

5. Plan rectification: rectify the problems discussed in the plan review.

6. The customer determines the design plan: the design plan is handed over to the customer, and the customer will finalize the plan according to their needs.

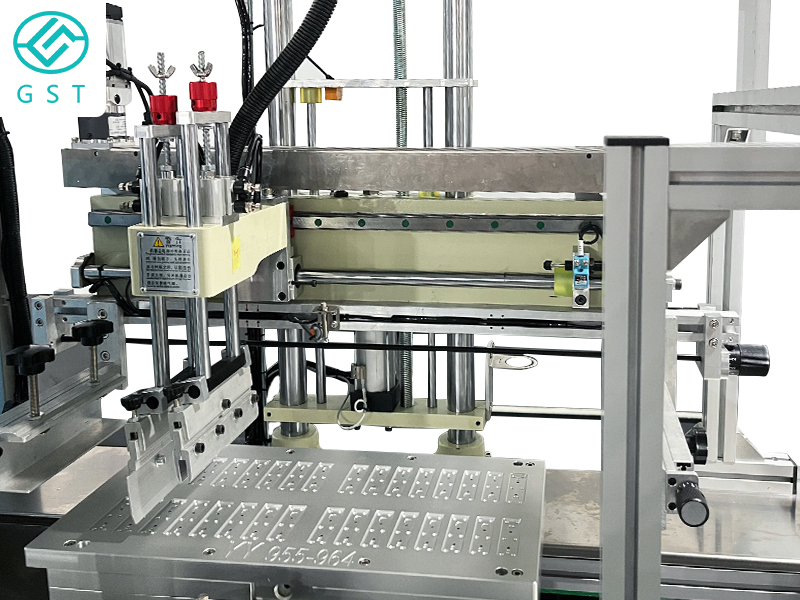

7. Design and development: The engineering department arranges engineers to design the mechanism, make machine assembly drawings and parts drawings (parts are marked according to national standards); select executive components, electronic control accessories and list processing parts list and standard parts requisition , the action manual.

8. Institutional audit: An audit team is formed by engineering personnel to audit the designed drawings.

9. parts processing and standard parts procurement.

10. Inspection and storage of processed parts and standard parts.

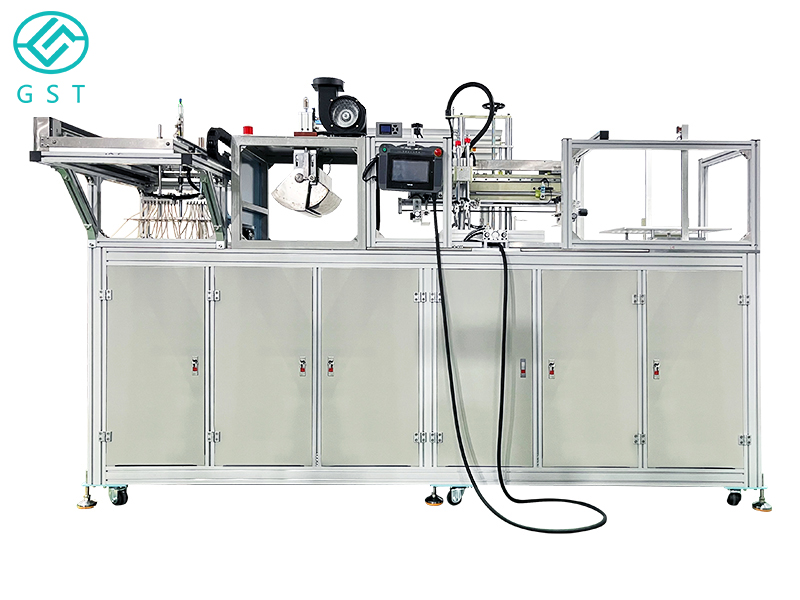

11. Machine assembly

12. Machine debugging

13. packing and shipping