Release Date:2024-03-14 11:51:45 Popularity:

With the rapid development of science and technology, fully automatic intelligent production lines are gradually becoming the new favorite of the manufacturing industry, leading an unprecedented production revolution. It not only greatly improves production efficiency and reduces costs, but also shows great advantages in product quality, flexibility and environmental sustainability.

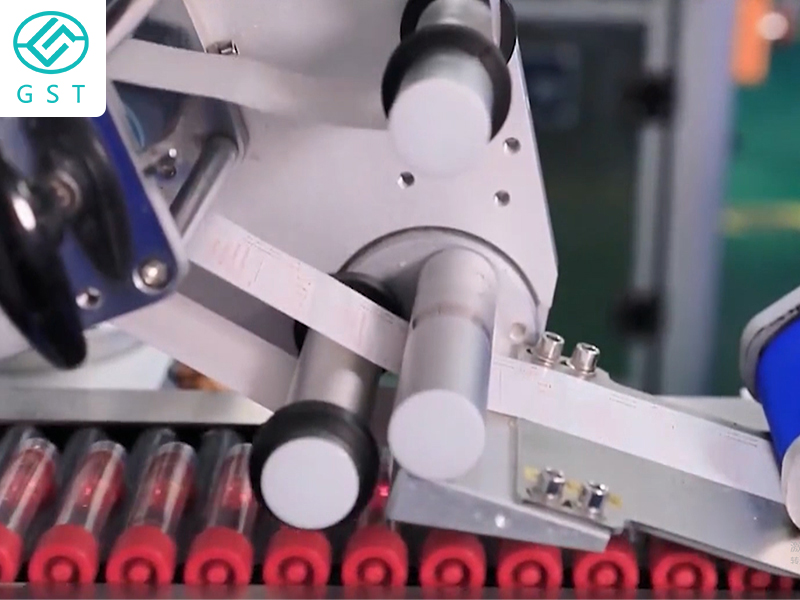

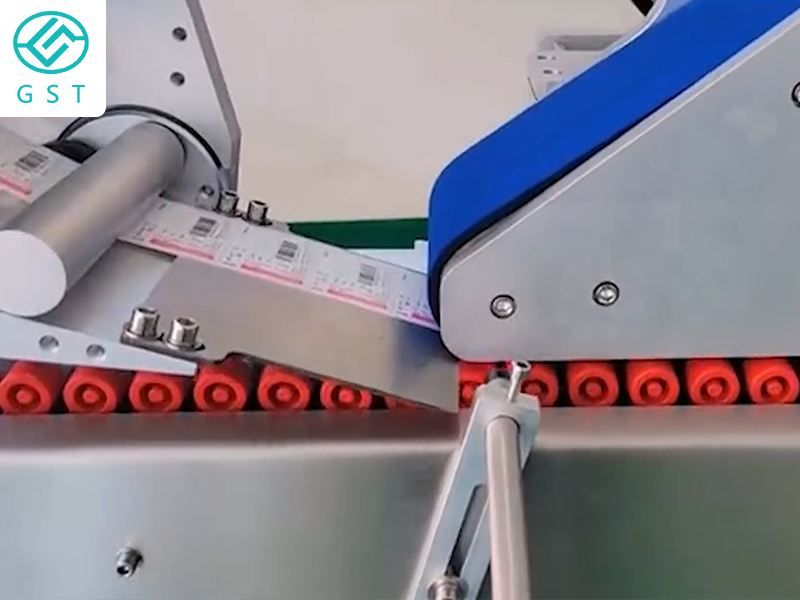

The fully automatic intelligent production line is a highly integrated production system that uses advanced automation equipment and intelligent control systems to achieve a seamless connection from raw materials to finished products. On this production line, robots and automated equipment have replaced traditional manual operations, and every production link has been carefully designed and optimized to ensure the continuity and stability of the production process.

In terms of production efficiency, fully automatic intelligent production lines have unique advantages. Traditional production lines are often limited by the speed and accuracy of manual operations, while fully automatic intelligent production lines can work uninterrupted for 24 hours, greatly improving production efficiency and output. In addition, through accurate data analysis and prediction, the production line can also achieve on-demand production to avoid resource waste and inventory backlog.

In terms of product quality, the fully automatic intelligent production line can achieve real-time monitoring and precise control of product quality by introducing advanced testing equipment and quality control systems. This not only greatly improves the product qualification rate, but also wins a better market reputation and customer trust for the company.

At the same time, the fully automatic intelligent production line also has extremely high flexibility. Through programming and parameter adjustment, the production line can easily adapt to the production needs of different products, achieving rapid production changes and customized production. This flexibility allows companies to quickly respond to market changes and meet customers' individual needs, thereby standing out in the fierce market competition.

In addition, the fully automatic intelligent production line also pays attention to environmental sustainability. During the production process, the production line can significantly reduce its impact on the environment by optimizing energy use, reducing waste emissions, and recycling. This not only meets the urgent demand for green production in today's society, but also wins a good social image and public recognition for the company.

Of course, the application of fully automatic intelligent production lines also faces some challenges and problems. For example, issues such as high investment costs, shortage of technical talents, and data security need to be properly addressed. However, with the continuous advancement of technology and the gradual reduction of costs, I believe these problems will be effectively solved.

As the future revolution of the manufacturing industry, fully automatic intelligent production lines are changing traditional production methods with their characteristics of high efficiency, precision, flexibility and environmental protection. It is not only an important direction for the transformation and upgrading of the manufacturing industry, but also an important force in promoting sustainable economic and social development. We have reason to believe that in the near future, fully automatic intelligent production lines will become the mainstream production method in the manufacturing industry, leading us into a new era of more intelligent, efficient and green production.