Release Date:2024-04-01 14:37:40 Popularity:

With the continuous advancement of science and technology and the rapid development of industry, traditional production lines have been unable to meet the efficient, flexible and personalized needs of modern manufacturing. In this context, non-standard automated production lines emerged as the times require and have become an important force in promoting industrial transformation and upgrading. This article will give you an in-depth understanding of the charm of non-standard automated production lines and how it can help companies realize the grand blueprint of intelligent manufacturing.

1. Non-standard automated production lines: definition and characteristics

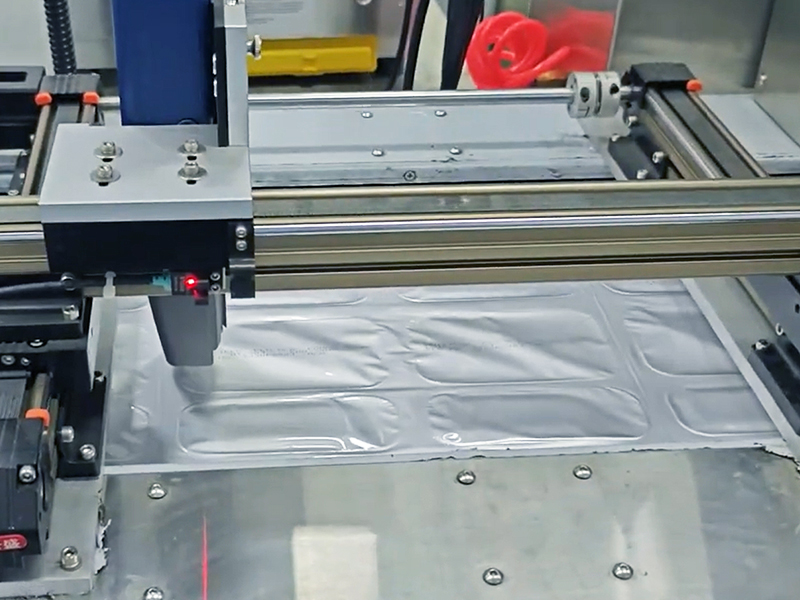

Non-standard automated production lines, as the name suggests, refer to non-standard automated production systems tailored according to the specific needs of customers. It is different from traditional standardized production lines in that it is highly flexible and customizable and can adapt to various complex and changeable production scenarios. The characteristics of non-standard automated production lines are mainly reflected in the following aspects:

Flexibility: Able to quickly adjust the layout and equipment configuration of the production line according to the production processes and processes of different products to achieve rapid line changeover.

Efficiency: Through the collaborative operation of automated equipment and intelligent control systems, production efficiency is greatly improved and manual intervention and errors are reduced.

Customization: Tailor-made production lines according to the special needs of customers to achieve personalized production and meet the diverse needs of the market.

Intelligent: Integrate advanced sensors, actuators and control systems to realize real-time monitoring and intelligent decision-making of the production process, improving the intelligent level of production management.

2. Application fields of non-standard automated production lines

Non-standard automated production lines are widely used in various industries, especially those fields that have special requirements for production processes, a wide variety of products, and small production batches. For example, in the manufacturing of auto parts, non-standard automated production lines can flexibly adjust the production line configuration according to the complexity of different models and parts to achieve efficient and precise production. In the electronics industry, non-standard automated production lines can meet the precision assembly and testing needs of various electronic components.

3. Advantages and challenges of non-standard automated production lines

The advantage of non-standard automated production lines lies in their high degree of flexibility and customizability, and their ability to quickly adapt to market changes and customer needs. At the same time, through the application of automation and intelligent technology, production efficiency and product quality can be greatly improved, and production costs can be reduced. However, non-standard automated production lines also face some challenges, such as high difficulty in design and manufacturing, rapid technological updates, and high customization costs.

4. Future Prospects

With the in-depth development of Industry 4.0 and intelligent manufacturing, non-standard automated production lines will usher in a broader development space. In the future, non-standard automated production lines will be more intelligent and flexible, and can better adapt to the rapid changes in the market. At the same time, with the application of advanced technologies such as artificial intelligence and big data, non-standard automated production lines will achieve more efficient production management and quality control, creating greater value for enterprises.

As an important part of intelligent manufacturing, non-standard automated production lines are leading the new trend of industrial manufacturing with their unique charm. Let us look forward to together, driven by non-standard automated production lines, the future manufacturing industry will become more intelligent, efficient and sustainable.