Release Date:2024-04-25 14:51:05 Popularity:

Liquid filling is an essential step in the production process of all walks of life. Whether it is the food industry, pharmaceutical industry or cosmetics industry, liquid product filling work needs to be carried out efficiently and accurately. As an efficient and intelligent filling equipment, small automatic filling machines are gradually becoming an important tool for enterprises to improve production efficiency and product quality. This article will deeply explore the working principle, characteristics and application value of small automatic filling machines in various industries.

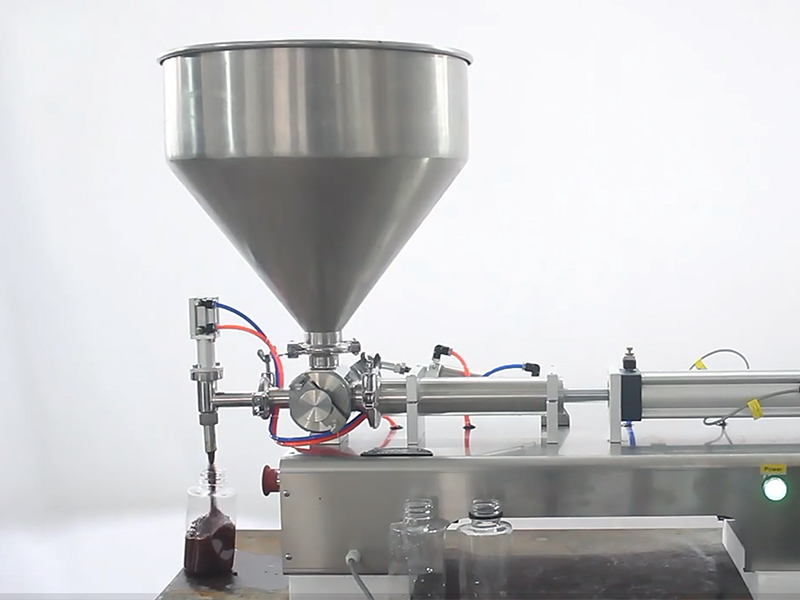

A small automatic filling machine is a device that uses advanced mechanical and electronic technology to realize automatic filling of liquid products. It quickly and accurately fills liquid products into packaging containers through a series of automated filling, metering, sealing and labeling operations. It is suitable for various types of liquid products, such as beverages, cosmetics, detergents, etc. . Compared with the traditional manual filling method, small automatic filling machines have the advantages of high work efficiency, low cost, and good filling consistency, and have become an important means for modern production enterprises to improve filling efficiency.

The small automatic filling machine has the following salient features:

1. High efficiency: The small automatic filling machine adopts advanced automation technology to achieve an efficient filling process. Through automated operation, filling efficiency can be greatly improved, labor costs can be reduced, and product production speed and quality can be improved.

2. Versatility: The small automatic filling machine has a variety of filling functions and can adapt to different types and specifications of liquid products. Whether it is small bottle filling or large bottle filling, whether it is a single product or the switching of multiple products, it can be realized through small automatic filling machines to meet the needs of different customers and markets.

3. Accuracy: The small automatic filling machine has high-precision filling capabilities and can achieve accurate measurement and filling of liquid products. This ensures the filling quality and consistency of the product and enhances the competitiveness of the product.

4. Intelligentization: With the development of artificial intelligence and Internet of Things technology, small automatic filling machines are gradually becoming intelligent. By introducing intelligent control systems and remote monitoring functions, intelligent identification, intelligent adjustment and intelligent optimization of equipment can be achieved, improving the equipment's adaptive capabilities and production efficiency.

In actual production, small automatic filling machines play an important role. It can realize fast and accurate filling of liquid products, ensure the filling quality and consistency of the product, and improve the competitiveness and market share of the product. Especially in the environment of small batch production and multi-variety production, small automatic filling machines can give full play to their advantages of high efficiency and high precision, saving costs and improving efficiency for enterprises.

In the future, as market competition continues to intensify and consumers' requirements for product quality and convenience continue to increase, small automatic filling machines will usher in a broader development space. The first is the development trend of intelligence. By introducing artificial intelligence and Internet of Things technology, small automatic filling machines can achieve intelligent production and management, improving production efficiency and product quality. The second is the development trend of flexibility. By introducing flexible manufacturing technology, small automatic filling machines can realize flexible layout and rapid adjustment of filling lines to adapt to rapid changes in market demand. In addition, the application of digital technology will further promote