Release Date:2024-05-21 11:36:59 Popularity:

In the booming development of the beer industry, technological innovation has always been one of the main driving forces for the development of the industry. As an important technology in the brewing industry, fully automatic beer filling machines are providing unprecedented convenience and efficiency in beer production with their high efficiency and precision. In this article, we will discuss the key features of fully automatic beer filling machines and their impact on the brewing industry.

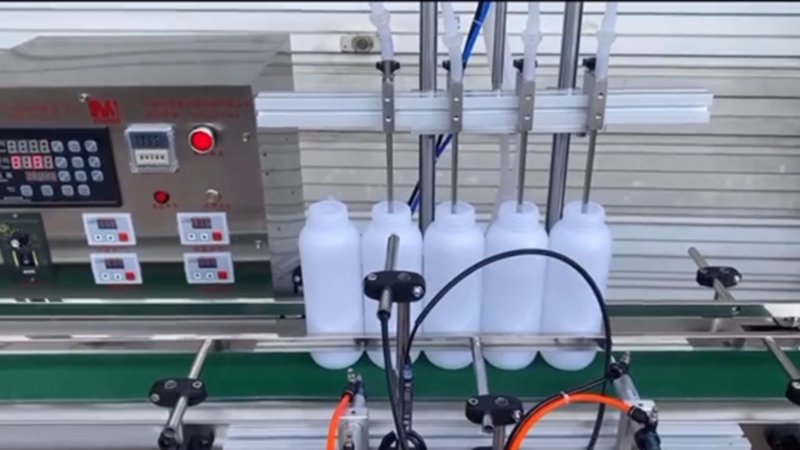

The fully automatic beer filling machine is a mechanical device that integrates an advanced control system, precision sensors and efficient actuators. Its working principle is based on a sophisticated automated process that is pre-programmed to deliver beer from storage tanks to bottles, jars or other containers, while ensuring accuracy and hygiene standards during the filling process.

Key features of fully automatic beer filling machine include:

1. Highly efficient production capacity: the automatic beer filling machine is capable of completing the filling task at a rate of thousands of bottles per hour, which greatly improves production efficiency and saves labor costs.

2. Accurate metering control: with the help of advanced sensors and control systems, the automatic filling machine can realize accurate monitoring and adjustment of beer flow, bottle quantity and filling volume to ensure the consistency of the quality of each bottle of beer.

3. Hygiene and safety guarantee: the automated filling process reduces human intervention and the risk of contamination, thus ensuring the hygiene and safety of the beer in line with the relevant food hygiene standards.

4. Flexibility and adaptability: the automatic filling machine can be adjusted according to different specifications and shapes of containers, applicable to a variety of packaging requirements, enhancing the flexibility and diversity of the production line.

The introduction of fully automatic beer filling machine has had a profound impact on the brewing industry:

1. Enhance production efficiency: automated filling makes the production process smoother and more efficient, greatly improving production capacity and helping to cope with rapid changes in market demand.

2. Optimize product quality: precise filling control ensures stable quality of each bottle of beer, which improves brand image and market competitiveness.

3. Reduce production costs: automated production reduces manual operation, reduces labor costs, and at the same time reduces the scrap rate, so that production costs can be effectively controlled.

4. Promote industry innovation: the continuous progress and application of technology to promote the innovation and development of the brewing process, and promote the industry to intelligent, digital direction.

As one of the key technologies in the modern brewing industry, the automatic beer filling machine has revolutionized beer production with its high efficiency and precision. With the continuous progress and application of science and technology, it is believed that fully automatic filling technology will continue to play an important role in injecting new power and vitality into the sustainable development of the brewing industry.