Release Date:2024-08-30 15:14:30 Popularity:

With the rapid development of science and technology, intelligent automation equipment is gradually becoming an indispensable core force in the manufacturing industry. Intelligent automation equipment not only significantly improves production efficiency, but also greatly improves product quality and reduces production costs. In this paper, we will discuss the definition of intelligent automation equipment, key technologies, application areas and the impact on the future of manufacturing.

First, the definition of intelligent automation equipment

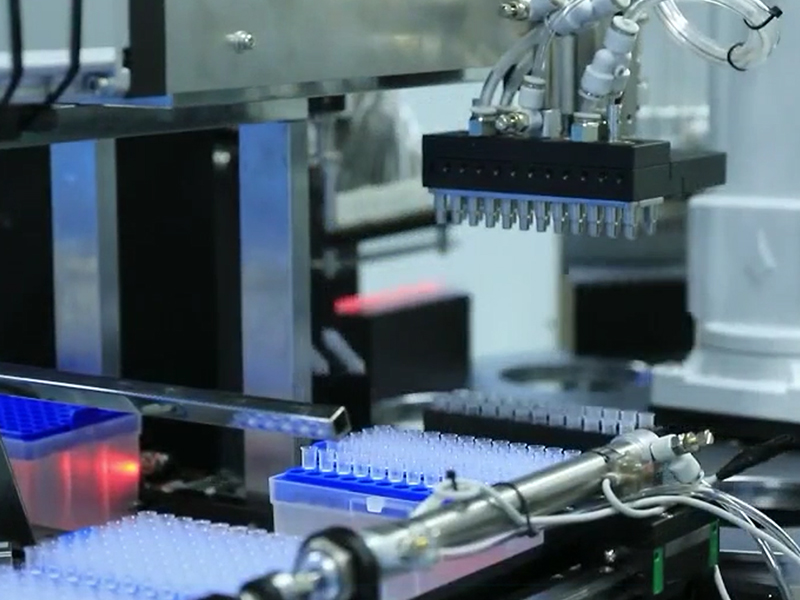

Intelligent automation equipment refers to the traditional automation equipment based on the integration of artificial intelligence (AI), Internet of Things (IoT), big data analysis, machine learning and other advanced technologies. Compared with traditional automation equipment, intelligent automation equipment is not only able to perform tasks according to predetermined procedures, but also has the ability to self-learn, self-optimize, and self-diagnose, thus enabling more flexible and efficient production.

These devices are usually equipped with sensors, control systems, actuators and other components, which can monitor various parameters in the production process in real time and make automatic adjustments through data analysis and artificial intelligence algorithms to ensure the stability of the production process and the consistency of product quality.

Second, the key technology of intelligent automation equipment

1. Artificial Intelligence (AI): Artificial Intelligence is one of the core technologies of intelligent automation equipment. Through AI algorithms, the equipment can identify and analyze a large amount of production data, from which to learn and optimize the production process.AI is also able to predict equipment failures, maintenance in advance, reduce equipment downtime and improve production efficiency.

2. Internet of Things (IoT): IoT technology enables intelligent automation devices to realize interconnectivity between devices. Through sensors and network connections, devices can obtain and share production data in real time, forming a collaborative intelligent production system. the application of IoT not only improves the transparency of production, but also makes remote monitoring and management possible.

3. big data analysis: in intelligent automation equipment, big data analysis is used to process and analyze the large amount of data generated during the production process. By analyzing this data, the equipment can optimize production parameters, predict market demand, and adjust production schedules to improve production flexibility and responsiveness.

4. Machine Learning: Machine learning enables intelligent automation equipment to have self-learning and adaptive capabilities. Through continuous learning and accumulation of experience, the equipment can make the best decisions in different production environments to improve production efficiency and product quality.

Third, the application fields of intelligent automation equipment

Intelligent automation equipment has been widely used in a number of industries, and significantly improve the productivity and competitiveness of various industries.

1. Manufacturing: In the manufacturing industry, intelligent automation equipment is widely used in automotive, electronics, machinery and other industries on the production line. Through intelligent production management, enterprises can realize mass customized production, quickly respond to market demand and reduce inventory costs.

2. Food and Beverage: In the food and beverage industry, intelligent automation equipment is used in production, packaging, inspection and other aspects. Through automated quality monitoring and data tracking, companies can ensure the safety and consistency of their products and meet strict health standards.

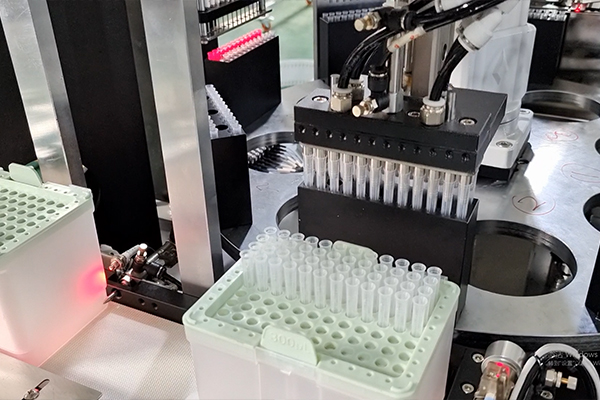

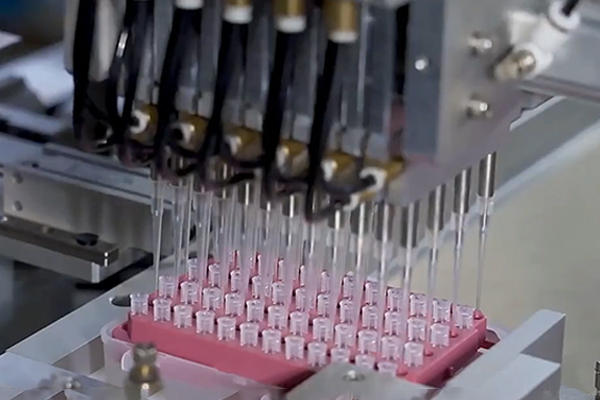

3. Pharmaceutical industry: The pharmaceutical industry has very high requirements for the production environment and product quality. Intelligent automation equipment can automatically complete the production, packaging and testing of drugs in a sterile environment, reducing human intervention and ensuring the quality and safety of drugs.

4. Logistics and warehousing: Intelligent automation equipment in the field of logistics and warehousing applications, including automatic sorting systems, automatic storage systems, unmanned handling equipment. These devices through intelligent algorithms and Internet of Things technology, can realize efficient material handling, inventory management and order processing, significantly improve logistics efficiency.

Fourth, the impact of intelligent automation equipment on the future manufacturing industry

The wide application of intelligent automation equipment is profoundly changing the production mode and competitive pattern of the manufacturing industry.

1. Enhance production efficiency: intelligent automation equipment significantly improves production efficiency through automation and intelligent operation. Enterprises are able to complete more complex production tasks in a shorter period of time, thus improving market response speed.

2. Reduce production costs: Intelligent automation equipment can optimize the production process and reduce the waste of energy and raw materials. At the same time, intelligent equipment maintenance and fault prediction functions can reduce equipment downtime, reduce maintenance costs.

3. Enhance product quality: Through real-time data monitoring and intelligent analysis, intelligent automation equipment can ensure the accuracy and stability of each production link, thus improving product consistency and quality.

4. Promote innovation: Intelligent automation equipment brings more innovation opportunities to the manufacturing industry. Enterprises can quickly launch new products to meet changing market demands through flexible production systems.

5. Cope with labor shortage: With the rising labor cost and aging population, intelligent automation equipment can help enterprises cope with labor shortage, realize unmanned production and reduce the dependence on manual labor.

Intelligent automation equipment, as an important driving force for future manufacturing, is triggering a productivity revolution worldwide. With the continuous development of artificial intelligence, Internet of Things, big data analysis and other technologies, intelligent automation equipment will be applied in more fields, bringing enterprises higher efficiency, lower costs and stronger market competitiveness. In the future, with the popularization of intelligent automation equipment and continuous technological innovation, the manufacturing industry will move towards a new era of more intelligent, efficient and sustainable development.