Release Date:2025-07-03 11:50:20 Popularity:

O-rings are widely used in industries such as mechanical seals, hydraulic components, and automotive parts. As a key sealing component, their assembly quality is directly related to the sealing effect and service life of the product. In order to solve the problems of low manual assembly efficiency and unstable quality, O-ring automatic assembly machines have become an important tool for many manufacturing companies to improve assembly efficiency and quality control levels.

I. Importance and assembly challenges of O-rings

O-rings are widely used in various mechanical equipment and fluid control systems due to their simple structure, excellent sealing performance, and low cost. Common application scenarios include: automotive engine systems, hydraulic cylinders, pneumatic valves, medical equipment, household appliances, etc.

During the assembly process, O-rings face the following challenges:

The material is soft and easy to deform, and it is easy to be scratched or twisted during manual installation;

Some structures are embedded and require precise positioning and uniform force;

Manual operation is inefficient in mass production and it is difficult to ensure consistency;

Special clean environments such as medical and electronic fields have extremely high requirements for the assembly process.

Therefore, the use of a dedicated O-ring automatic assembly machine can effectively solve the above problems and achieve high-precision and high-stability automatic assembly.

II. Functions and composition of O-ring automatic assembly machine

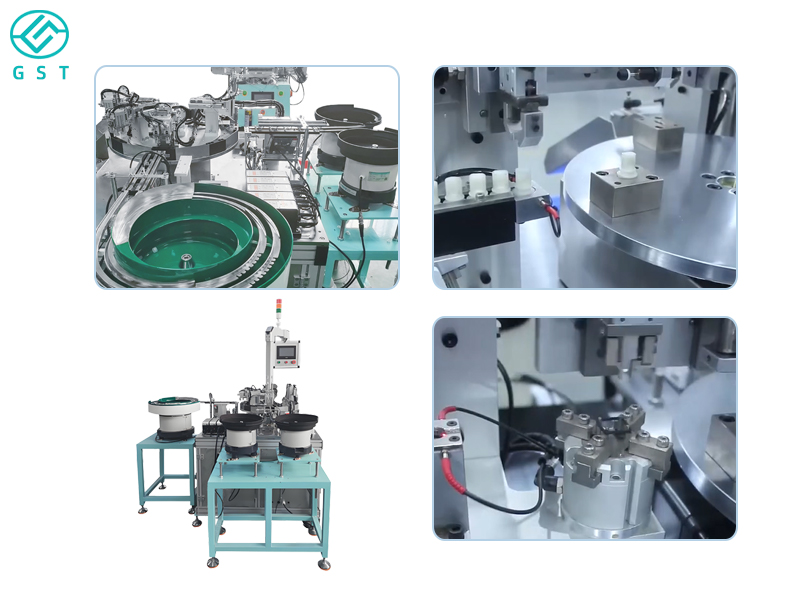

The O-ring automatic assembly machine is a high-end automation equipment that integrates automatic feeding, precise positioning, flexible grabbing, automatic pressing, quality inspection and other functions. It has the following system modules:

Automatic feeding system: using vibration plate, feeding conveyor belt, silo and other devices to accurately sort and directional output O-rings and assembly parts to improve feeding efficiency and stability.

Positioning and assembly module: using visual system or limit fixture to achieve accurate alignment of assembly parts and O-rings to avoid deviation.

Flexible clamping and pressing mechanism: through pneumatic clamps or servo drive devices, evenly load O-rings into corresponding slots to avoid damage due to excessive stretching or uneven force.

Quality inspection system: equipped with CCD visual recognition system, it can monitor in real time whether the O-ring is assembled in place, whether it is damaged, whether there are missing parts, etc., and automatically remove defective products.

Intelligent control system: adopts PLC control + touch screen operation interface, supports parameter setting, data recording, alarm prompts and network monitoring functions.

III. Equipment advantages

High efficiency: A single machine can achieve stable assembly of dozens or even hundreds of O-rings per minute, greatly improving the efficiency of the production line.

High precision: With the help of high-precision positioning system and servo drive technology, it ensures accurate assembly and good sealing.

Low loss: effectively avoids scratches, tears, missing installation and other problems during manual installation, and improves the product qualification rate.

High compatibility and strong customization: The fixtures and programs can be customized according to different product structures to meet the assembly needs of O-rings and parts of various sizes and materials.

Save labor costs: replace 2~5 skilled workers and reduce operator training and management pressure.

Intelligent traceability and data visualization: Real-time collection of assembly data, supporting industrial IoT applications such as production statistics, quality traceability, and remote fault diagnosis.

The application of O-ring automatic assembly machines represents the intelligent improvement of manufacturing in subdivided process flows, and is an important boost to promote the transformation of enterprises from labor-intensive to technology-driven. It not only greatly improves assembly efficiency and quality control capabilities, but also helps enterprises reduce costs, enhance competitiveness, and achieve sustainable development.