Release Date:2025-07-05 11:30:58 Popularity:

The manufacturing process of pipettes has strict requirements on dimensional accuracy, cut smoothness, product consistency, etc., especially in the cutting process, any burrs, debris or length deviation may affect subsequent use. In order to improve production efficiency and cutting quality, pipette automatic tube cutting machines, as efficient and intelligent key equipment, are playing an increasingly important role in the laboratory consumables manufacturing industry.

1. Difficulties in pipette cutting process and limitations of traditional methods

In the production process of pipettes, plastic embryo tubes (usually made of polystyrene or polypropylene) need to be accurately cut into specified lengths to match different capacity specifications (such as 1mL, 5mL, 10mL, 25mL, etc.). Traditional cutting methods mostly rely on manual or semi-automatic pipe cutting machines, which have the following problems:

Large dimensional error: manual measurement and operation cannot guarantee uniform cutting length;

Poor incision quality: burrs and debris are easily generated, affecting sealing and user experience;

Low efficiency and high labor intensity: manual operation is slow and cannot meet the needs of mass production;

High defective rate: frequent human errors and high quality inspection costs.

Therefore, the use of a dedicated pipette automatic pipette cutting machine can effectively solve the above problems and realize one-stop automated operation from fixed length, cutting to material collection.

2. Functional composition and operation principle of pipette automatic pipette cutting machine

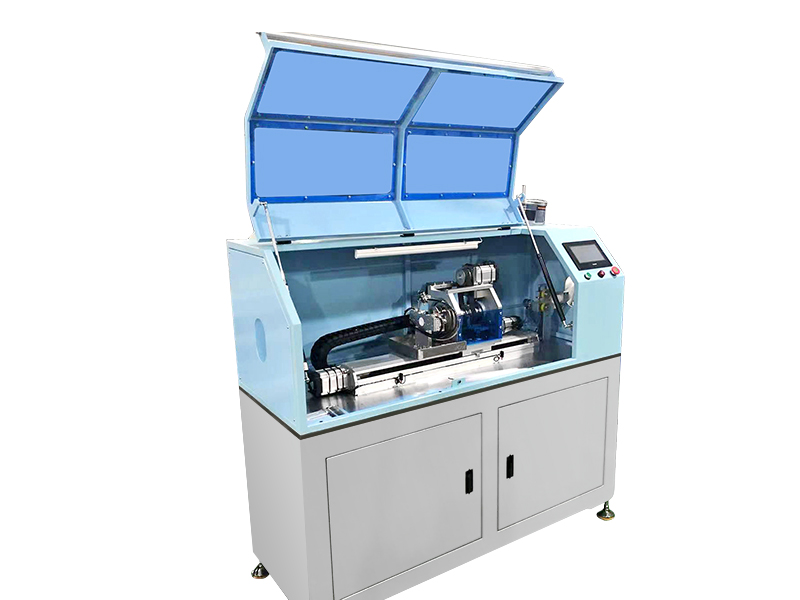

The pipette automatic pipette cutting machine is an intelligent device that integrates automatic feeding, length setting, precision cutting and automatic material distribution. Its main structure and functional modules include:

Automatic feeding system: using vibration plate, roller feeding or feeding conveyor belt to realize continuous feeding of embryo tubes and ensure uninterrupted production rhythm.

Positioning and length-fixing device: The servo motor cooperates with the precision guide rail to ensure that each pipe is accurately measured and fixed before entering the cutting station.

High-speed cutting system: Equipped with a rotating blade, ultrasonic knife or laser cutting head, the cutting edge is smooth and burr-free, and the length tolerance can be controlled within ±0.1mm.

Cut cleaning treatment: After cutting, the debris is automatically blown to ensure the cleanliness of the tube and meet the cleanliness requirements of experimental consumables.

Intelligent sorting and material collection system: Classify and unload materials according to the set length or model, which can be seamlessly connected with subsequent stretching, plugging, and packaging processes.

Control system: PLC control and human-machine interface (HMI) operation platform are adopted to support parameter setting, real-time monitoring, alarm prompts and data statistics.

3. Equipment advantage analysis

High cutting accuracy and consistency: Automatic positioning and servo control system ensures that the length of each pipette is accurate, the cut is smooth and burr-free, and the product qualification rate is improved.

Production efficiency is greatly improved: a single machine can cut dozens to hundreds of pipes per minute, far exceeding manual operation, meeting the needs of large-scale continuous production.

Save labor costs: replace multiple workers, reduce the number of operators and training pressure, and reduce employment costs.

High safety and stability: the closed cutting structure avoids the harm of flying chips and noise to operators, the equipment has strong operating stability, and can achieve long-term continuous work.

Multi-specification compatibility, convenient switching: supports fast switching of pipettes of different diameters and lengths, just adjust the parameters or replace the corresponding fixtures.

Clean production, in line with medical standards: the whole machine is made of stainless steel or aluminum alloy, easy to clean, and meets GMP, ISO13485 and other medical consumables production standards.

As an indispensable intelligent device in the manufacturing process of experimental consumables, the automatic pipette cutting machine not only solves the pain points of traditional cutting technology, but also plays a key role in production efficiency, product quality and enterprise automation upgrades.