Release Date:2025-07-19 11:54:19 Popularity:

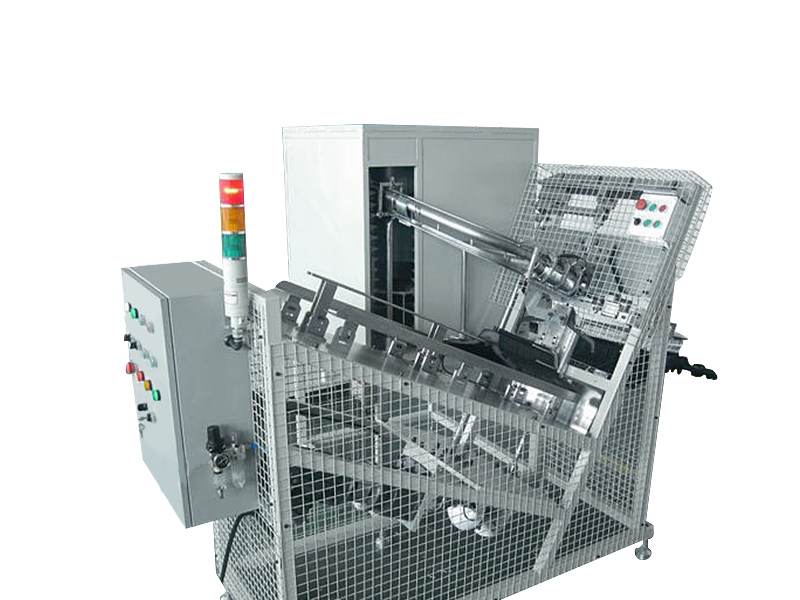

The automatic hanger hook insertion machine is an intelligent device that integrates mechanical, pneumatic and servo control. It is specially used to automatically insert metal or plastic hooks into the hanger body. It transforms the hook insertion process that originally required manual operation into a high-speed, precise and stable automated production process through a series of processes such as automatic feeding, positioning, hook assembly and finished product delivery. The equipment is suitable for various types of plastic hangers, wooden hangers, flocked hangers and other products, and supports rapid replacement and adjustment of various sizes and hook types.

1. Working principle and main structure of the equipment

The automatic hanger hook insertion machine is generally composed of the following core modules:

Hanger conveying and positioning module: The belt conveyor system or turntable device is used to transport the hangers to the hook insertion station in an orderly manner, and the positioning fixture is used to ensure the accurate position of the hangers when the hooks are inserted.

Hook automatic feeding system: With the help of a vibrating plate or a spiral elevator, the bulk hooks are automatically straightened and arranged, and sent to the hook insertion mechanism.

Hook insertion mechanism: Servo pressing or pneumatic drive is used to accurately press the hook into the reserved hole of the hanger to ensure a firm connection without damaging the hanger body.

Finished product conveying and inspection module: After the hook is inserted, the hanger is automatically transported to the next station or collection area, and an online inspection system can be configured to detect and screen the quality of the hook.

Control system: The equipment is equipped with a human-machine interface (HMI), which is easy to operate and supports parameter adjustment, counting, alarm and other functions, and is suitable for a variety of production needs.

2. Advantages of automatic hanger hook insertion machine

Improve production efficiency: Traditional manual hook insertion takes about 58 seconds per piece, while the automatic hook insertion machine can achieve high-speed production of 1.53 seconds per piece, significantly improving production capacity.

Reducing labor costs: One device can replace 2 to 4 skilled workers, especially suitable for areas with labor shortages or high labor costs.

Ensure product consistency: The automatic assembly method has extremely small errors, which can effectively avoid quality problems such as skewness and looseness caused by manual assembly, and improve the qualified rate of finished products.

Adapt to various hanger types: supports quick mold replacement, suitable for hangers of various models and materials, greatly improving the versatility and flexibility of the equipment.

Simple operation and convenient maintenance: full automation control, humanized operation interface, long maintenance cycle, low failure rate, greatly reducing the burden on workers.

As one of the important equipment for the automation transformation of the hanger production industry, the automatic hanger hook insertion machine is accelerating the replacement of traditional manual operation methods, which not only promotes enterprises to reduce costs and increase efficiency, but also provides a strong guarantee for the stability of product quality and market competitiveness.