Release Date:2025-08-01 11:49:32 Popularity:

Customized automatic packaging machines have become a key tool for many manufacturers to improve production efficiency, optimize packaging processes, and enhance product competitiveness. With the increasing trend of market segmentation, products are becoming more diverse in specifications, shapes, and packaging materials, placing greater demands on packaging equipment for flexibility and precision.

1. The Core Advantages of Customized Automatic Packaging Machines

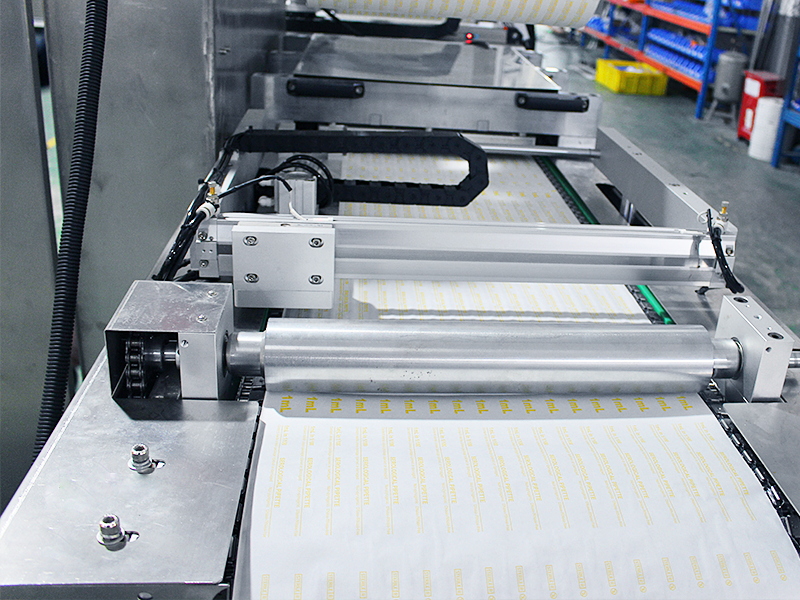

Highly Compatible with Production Processes: The most significant advantage of customized automatic packaging machines lies in their high degree of customization. Manufacturers design customized mechanical structures and control systems based on the specific attributes of the customer's product, such as material form (granular, powder, liquid, paste), packaging format (bag, bottle, box), and packaging specifications. This ensures a smooth and efficient packaging process while minimizing material waste.

Improving Packaging Efficiency and Quality: Compared to traditional equipment, customized automatic packaging machines can optimize packaging speeds and weighing accuracy based on production cycles. This ensures efficient operation while ensuring consistent, aesthetically pleasing, and airtight packaging, enhancing the final product's market image.

Optimize Space and Production Line Layout: Customized packaging machines can be modularly designed to suit the customer's factory space and existing production line layout. Flexible integration of feeding, weighing, filling, sealing, coding, and inspection processes ensures seamless integration between the equipment and production line, helping companies achieve comprehensive automation upgrades.

Strong Scalability to Meet Future Growth: Customized equipment often utilizes a modular design concept, facilitating the subsequent addition of functional modules (such as automatic labeling, automatic case packing, and visual inspection) to meet the needs of future production expansion and product upgrades.

2. Customized Automatic Packaging Machines Have a Wide Range of Applications

Customized automatic packaging machines are widely used in various industries, with particular strengths in the following areas:

Food Industry: Automated quantitative packaging of seasonings, nuts, frozen foods, and puffed foods;

Pharmaceutical Industry: Precision packaging of tablets, granules, and powders, requiring high cleanliness and precision;

Daily Chemical Industry: Liquid and paste products such as laundry detergent, shampoo, and facial cream;

Hardware and Electronics: Quantitative packaging of special-shaped materials such as screws, plugs, and components;

Agricultural Products: Automated packaging solutions for seeds, fertilizers, and feed.

Customized automatic packaging machines can provide precise and efficient system solutions for packaging needs in various industries.

3. Key Criteria for Selecting a Customized Automatic Packaging Machine Manufacturer

To achieve efficient and stable customized packaging solutions, it is crucial to select a manufacturer with strong technical capabilities. Key areas to consider include:

R&D and Design Capabilities: Does the company have an independent R&D team capable of quickly designing feasible and reasonable solutions for non-standard requirements?

Industry Experience and Case Studies: Does the company have proven experience with customized projects in related industries, providing references and case studies.

Manufacturing and Assembly Capabilities: Is the equipment meticulously crafted, the components made of high-quality materials, and does the company have a rigorous assembly and commissioning process?

After-Sales Service: Customized equipment relies heavily on after-sales service. Does the manufacturer offer responsive technical support and spare parts service?

In short, customized automatic packaging machines offer more than just technological innovation at the equipment level; they also serve as a crucial bridge for businesses to achieve digital and intelligent transformation. They tailor the optimal packaging process for businesses, improving production efficiency and product quality while also giving them a competitive edge in the fierce market. Choosing a professional provider of customized automatic packaging machines means choosing a future of efficient, stable, and sustainable production.