Release Date:2025-08-04 11:20:51 Popularity:

Amid the current surge in industrial intelligence, standardized equipment is no longer able to meet the demands of some companies for personalized, flexible, and efficient production models. More and more companies are turning to custom manufacturers of non-standard automation equipment to create tailored solutions to address complex, unique, or precise production needs. In this niche market, Guanshentai Automation Equipment, with its deep technical expertise, extensive industry experience, and exceptional custom engineering capabilities, has become a trusted partner for many manufacturers.

1. The Importance of Custom Manufacturers of Non-standard Automation Equipment

As the name suggests, non-standard automation equipment differs from standard production lines and is tailored to specific needs. Whether in the medical device, electronic component, plastic product, daily chemical product, hardware, home appliance, or packaging industries, many processes are difficult to implement with standard equipment due to specialized product structures, complex production processes, or unique process flows.

This requires that non-standard equipment not only meet specific functional requirements but also consider a wide range of factors, including the equipment's spatial structure, upstream and downstream integration, degree of automation, and scalability. This also places higher demands on the custom manufacturer's R&D capabilities, machining expertise, and project delivery experience.

2. Guanshentai: A Premium Brand for Customized Non-standard Automation Equipment

As a manufacturer of customized non-standard automation equipment with many years of experience, Guanshentai adheres to the philosophy of "technology-focused, quality-first, and service-oriented." We are committed to providing customers with high-efficiency, low-energy, and intelligent customized solutions, serving a wide range of industries, including biomedical, plastics, electronics manufacturing, and household goods.

1. Significant Customization Advantages: Guanshentai understands that every customer's needs are unique. From initial research and technical solution design to mid-term mechanical assembly, electronic control programming, and complete machine commissioning, and finally to on-site installation and after-sales service, Guanshentai adheres to a full-process customization model to ensure that our equipment precisely meets customer production needs.

2. Strong Technical Team: The company boasts a technical R&D team comprised of mechanical engineers, electrical engineers, and automation control experts. We can quickly develop highly feasible solutions based on customer-provided product drawings or process requirements.

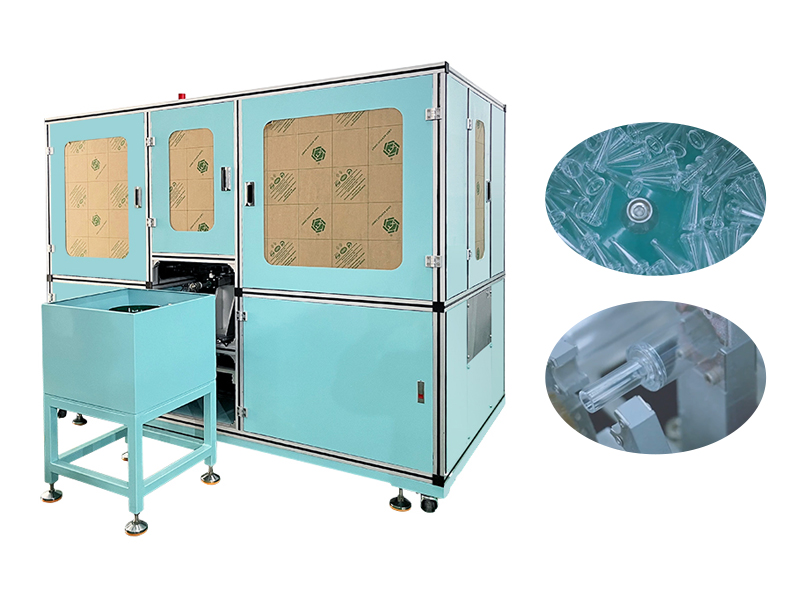

3. Extensive Industry Experience: Guanshentai's custom-made equipment encompasses a wide range of modular products, including automated assembly machines, automated filling lines, automated packaging systems, CCD visual inspection systems, and robotic integration solutions. These products have been widely used in a variety of applications, including pipettes, centrifuge tubes, tips, hangers, dental mirrors, and cryopreservation tubes, earning widespread acclaim from customers.

4. Precision Manufacturing and Quality Assurance: All equipment components are processed using high-precision CNC machining and adhere strictly to ISO quality system standards, ensuring stable operation of every unit, achieving high productivity and minimal failure rates.

3. Reasons Why Customers Choose Guanshentai

Why do so many companies prioritize Guanshentai when choosing a custom manufacturer for non-standard automation equipment? This is due to the following:

Professional project management process: From requirements communication to delivery and acceptance, dedicated personnel are assigned to each step to ensure progress and quality.

Quick response and after-sales service: 24/7 service ensures rapid response to any equipment issues.

Continuous optimization and technology upgrades: Supports future functional expansion and module upgrades to meet the company's future development needs.

Cost-effective solutions: Achieve high-level automation within a reasonable budget, truly helping customers reduce costs and increase efficiency.

Faced with the increasingly competitive manufacturing market, traditional production methods can no longer meet the dual requirements of efficiency and quality in the new era. Customized automation equipment has become key for companies to break through bottlenecks and enhance core competitiveness. Choosing a custom manufacturer with extensive experience and advanced technology is undoubtedly the first step towards intelligent transformation. If you are looking for an automation equipment partner who can provide tailored solutions, consider Guanshentai and embark on a new journey of intelligent manufacturing!