Release Date:2022-09-24 10:20:38 Popularity:

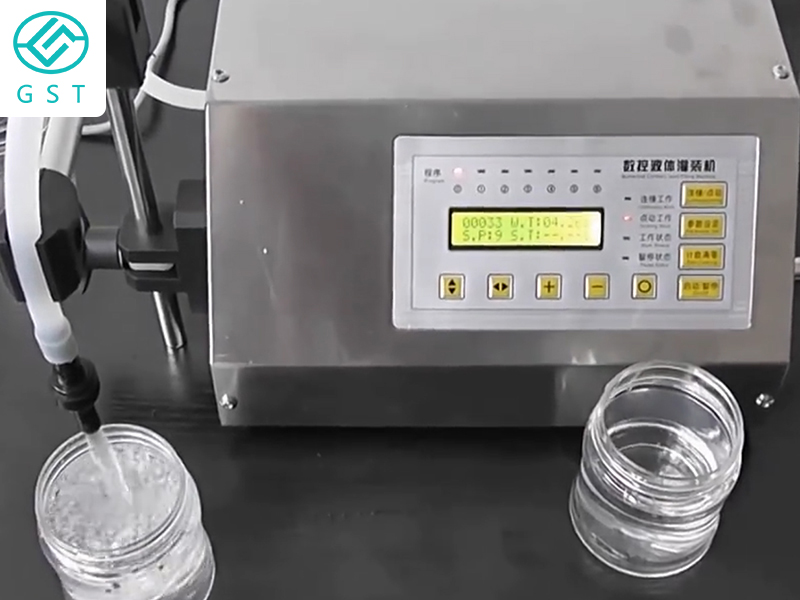

The volumetric semi-automatic filling machine adopts the volumetric method of metering, and the filling volume is controlled by adjusting the plunger volume; the front end of the inlet is equipped with a feed pump or raw material storage tank to send the material from the tank to the filling machine by means of pressurisation, and a filtering device can be added to remove impurities before filling to ensure product quality; the reciprocating movement of the piston enables fast filling; the equipment has the advantages of high filling efficiency and easy maintenance, and is used in Paint, ink, paint, asphalt, glue, lubricants, petrochemicals, fine chemicals and other industries have a wide range of applications, suitable for high, medium and low viscosity fluid filling.

1、Product advantages of volumetric semi-automatic filling machine

Fast filling speed and wide range of application: the filling head can be single or double head, piston type work, high filling speed, cost saving, reduce the work pressure of workers; can be suitable for round, square, flat and various calibres of filling.

Convenient operation, easy maintenance: foot switch operation, convenient and practical, one person can complete the operation, equipped with all imported components, stable and reliable quality.

Excellent environmental protection indicators, safety: full pneumatic control, in line with the requirements of explosion-proof; filling feed using pipeline connection, filling is completed quickly after the completion of capping/clamping work, less solvent volatilization, good site environment.

2、Working principle of volumetric semi-automatic filling machine

The inlet valve opens, the outlet valve closes, the piston rod draws back and pumps the material from the raw material tank to the piston chamber; close the inlet valve, open the outlet valve, the piston rod pushes forward and sends the material from the piston chamber to the tank; it works reciprocally and is equipped with conveying roller conveyor and lid pressing/clamping device to complete the material filling and sealing process.