Release Date:2022-10-05 10:03:50 Popularity:

Laundry detergent is gradually replacing washing powder in life, not only does not hurt the hands and can wash clothes clean, but also liquid detergent is becoming the choice of the public. This is also inseparable from the automatic cleaning liquid filling machine assistance.

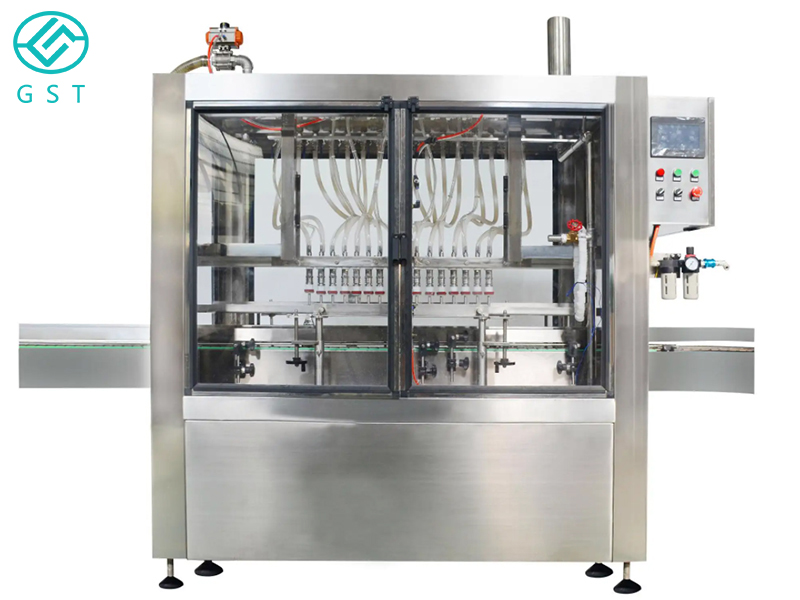

Machine layout is reasonable, all stainless steel, mostly used for paste materials are mainly detergent, laundry detergent, daily necessities, laundry products, cosmetics and other major categories, the main electrical components are used at home and abroad well-known brands, filling high precision, filling volume and filling speed adjustment is convenient. The machine is designed as a linear multi-station production line, which can be configured according to the actual needs of customers to complete quantitative automatic filling, capping or capping, electromagnetic induction aluminium foil sealing, etc. It can also be combined into automatic production lines such as automatic bottle feeding, filling, capping, coding, labelling, automatic case packing and case sealing.

This detergent filling machine can be perfectly adapted to the filling of different shapes and capacities (plastic bottles, tin cans, stand-up pouches) and other packaging containers, filling accurately, quickly and without dripping, referring to foreign advanced filling machine technology, and improved according to the actual needs of the domestic model, is currently the domestic economic, high technology content, but also good stability and reliable filling equipment for detergent, laundry detergent.

Method of use.

1. the machine must be well grounded before work, and then according to the different dispensing volume to choose the appropriate standard syringe. The general dispensing range is 100ml model, use 100ml glass enema, (also use the special stainless steel filling system produced by the factory); 500ml model, use the special stainless steel filling system produced by the factory.

2. Turn out the inner core of the syringe and put the screw sleeve on the inner core of the syringe.

3. the upper clamp seat on the syringe jacket outlet end, the two sides of the nut will be properly tightened (with 5ml syringes will be set together with the bushing tightened, pay attention to the tightening of too tight, the jacket tube fragile).

4. will be installed in the syringe core, jacket assembly into one, so that the liquid injection system assembly is complete.

5. Fix the valve with the arrow facing up and the arrow mark facing out with the nut on the fixing screw.

6. will be assembled complete injection system, the injection system components, the upper and lower round hole, respectively, aligned with the upper and lower fixed rod, set on the bearing, and make its outer surface and bearing surface flat. When assembling the lower end, do not allow the sleeve to touch the crank to prevent the upper crank from rotating with an abnormal sound (about 1mm between the sleeve and the crank when correctly installed), after the injection system is correctly installed, tighten the upper and lower set screws. Use a short hose to connect the syringe to the valve connection nozzle. The liquid inlet pipe is connected to the water inlet and the liquid outlet pipe to the water outlet. To prevent the inlet and outlet pipes from becoming entangled, snap the inlet and outlet pipes into the side of the housing.

7. Turn the crank handle by hand, it should be able to rotate freely, otherwise the assembly is wrong, and the liquid injection system should be checked to see if it is fastened to the rotating bearing.