Release Date:2022-12-15 14:50:27 Popularity:

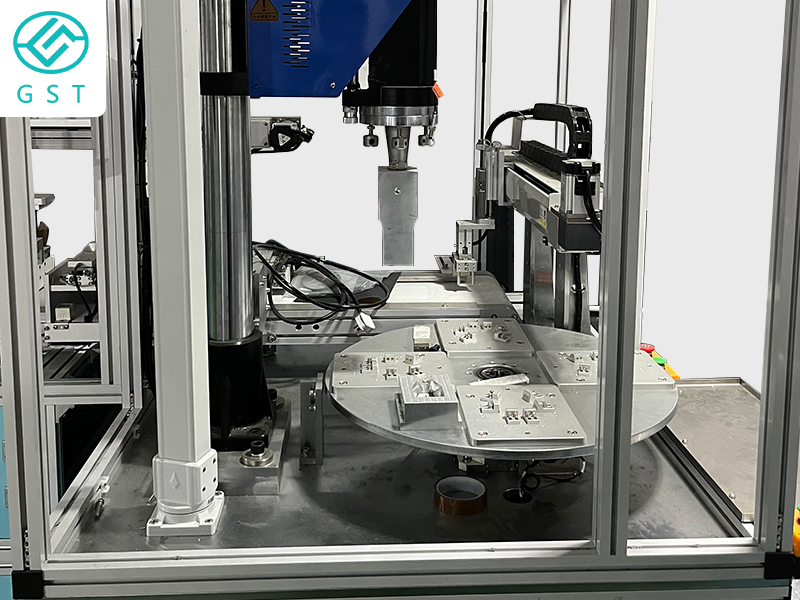

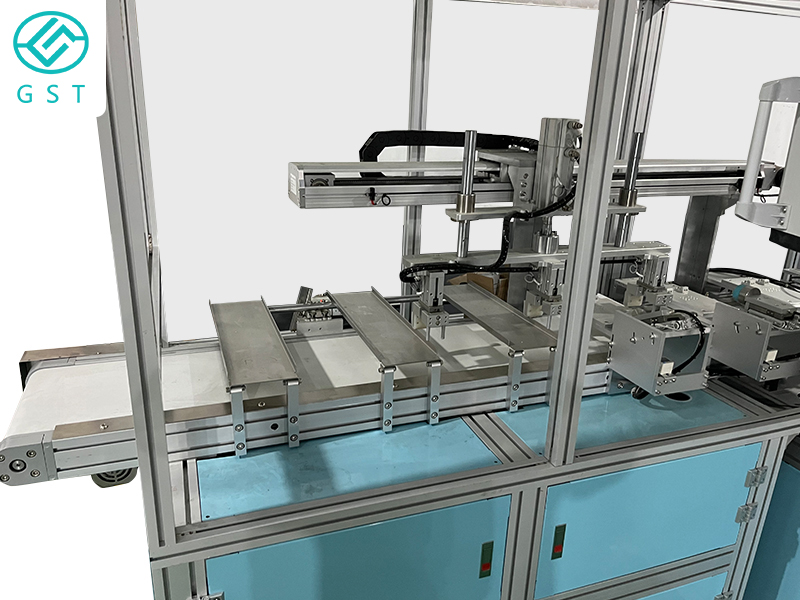

GST culture bottle automatic ultrasonic welding machine is a technology that uses ultrasonic waves to weld plastic workpieces. This advanced technology can be widely used in various industries when applied to plastic welding machines, including auto parts industry, medical industry, and electronic device industry. , daily necessities industry, etc.

GST culture bottle automatic ultrasonic plastic welding technology not only has a wide range of applications, but also has the advantages of fast efficiency, high precision, low cost and environmental protection, and has been favored by many enterprises. The technology is very good, but not everyone understands it very well, and there are even misunderstandings. The following will introduce the common misunderstandings of ultrasonic welding.

1. The higher the power of the ultrasonic welding machine, the better

This point of view is incorrect. The power of the ultrasonic welding machine is not the bigger the better, it needs to be determined according to the actual needs of product welding. Ultrasonic output power, diameter and size of piezoelectric ceramic sheet, thickness, material, design process and other factors are determined.

The greater the power of the GST culture bottle automatic ultrasonic welding machine, the larger the volume of the fixed installation machine, and the larger the diameter of the cylinder, which will affect the speed of the ultrasonic welding machine. However, the ultrasonic power is not enough, and the plastic workpiece is easy to be welded weakly, and even causes problems such as internal damage of the product.

2. The selection of the welding head of the ultrasonic plastic welding machine is based on the material

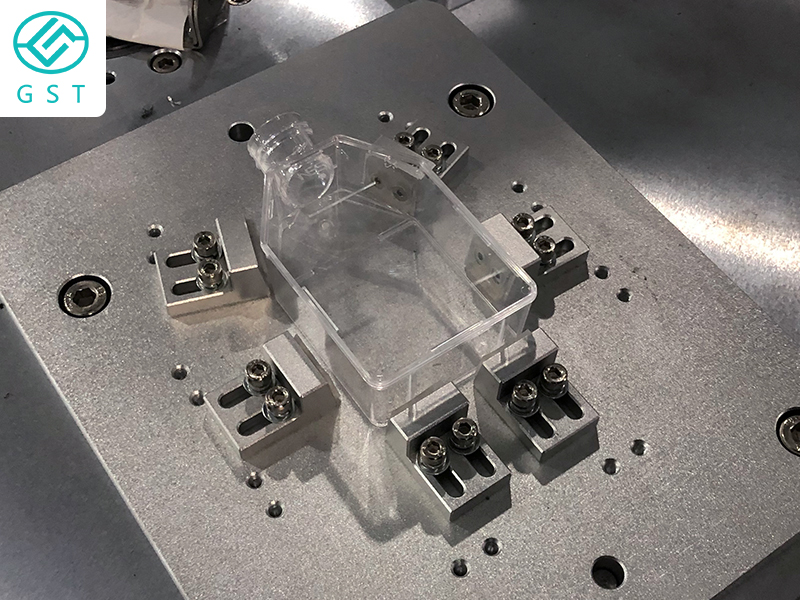

This point of view is incorrect. The material selection of the welding head of the ultrasonic plastic welding machine is important, and the quality of the welding head (HORN) material can determine the product qualification rate. If the welding head is made of inferior materials, not only can the product be intact, but the welding head is also prone to cracking, causing damage to power components and other adverse factors.

The design of the welding head is also very important, and its design is mainly adjusted according to the strict calculation of the plastic workpiece. The design of the welding head affects the efficiency and life of the welding head, and also affects the qualified rate of the product. Choosing an unreasonably designed welding head can cause the generator to burn out in severe cases.

3. Any material can be processed by plastic welding machine

This point of view is biased. When the ultrasonic welding machine is working, it is necessary to consider whether the melting point of the plastic parts is similar, the requirements of the welding accuracy of the plastic parts, and so on.

There are strict requirements for the selection of materials for plastic workpieces. For thermoplastics, the selection of materials is very important for product production. Another reason is that some materials are difficult to weld, such as nylon.