Release Date:2023-06-26 11:12:54 Popularity:

The filling of liquid products is an important and common production process in many industries. In order to improve production efficiency and ensure product quality, many companies have begun to use semi-automatic liquid filling machines. This article will deeply discuss the principle, advantages and application fields of the semi-automatic liquid filling machine, and introduce its key role in production in detail.

A. Overview of semi-automatic liquid filling machine

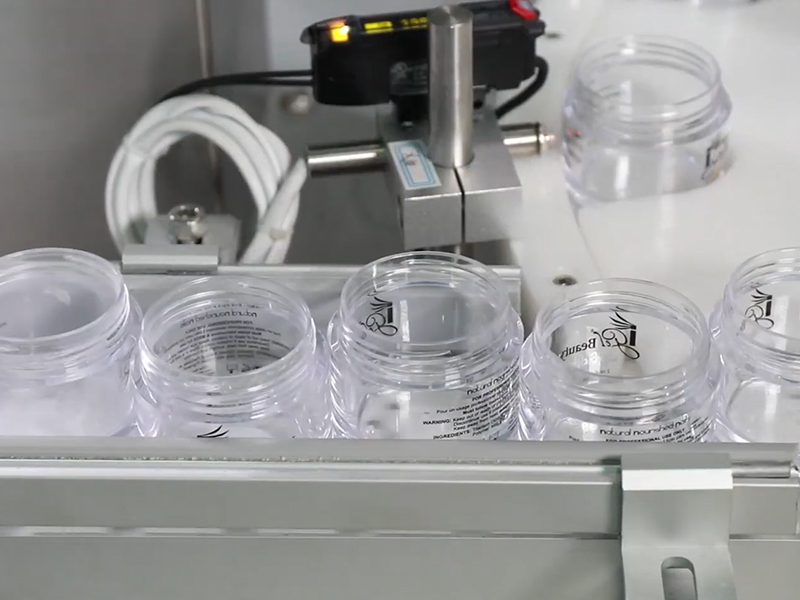

The semi-automatic liquid filling machine is a liquid filling equipment that integrates automatic operation and manual assistance. Compared with automatic liquid filling machines, it is easier to operate, suitable for smaller production lines, and has lower investment costs. Semi-automatic liquid filling machines combine mechanical movement and human intervention to enable an efficient liquid filling process.

B. Advantages of semi-automatic liquid filling machine

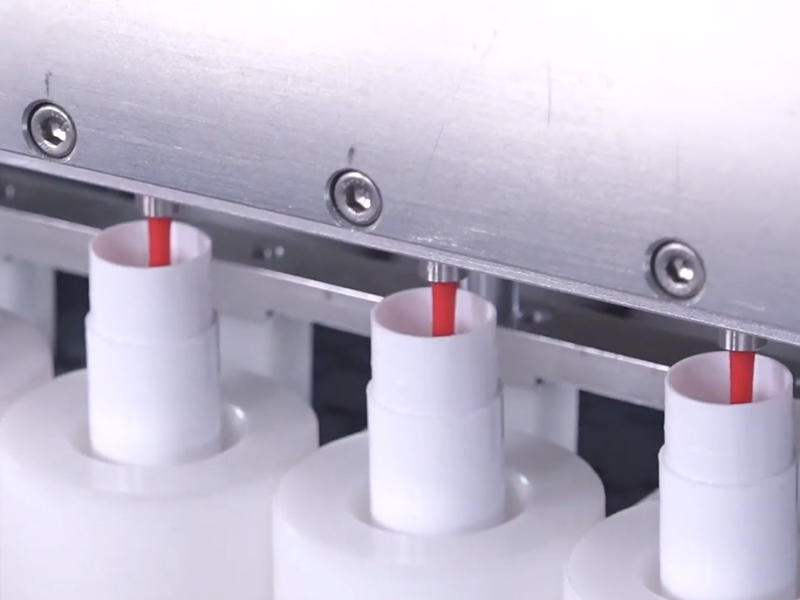

1. Improve production efficiency: The semi-automatic liquid filling machine can greatly improve the filling speed of liquid products through automatic operation. Compared with the traditional manual filling, the semi-automatic liquid filling machine can realize the continuous filling process, reduce the filling time, and can meet the higher production capacity demand.

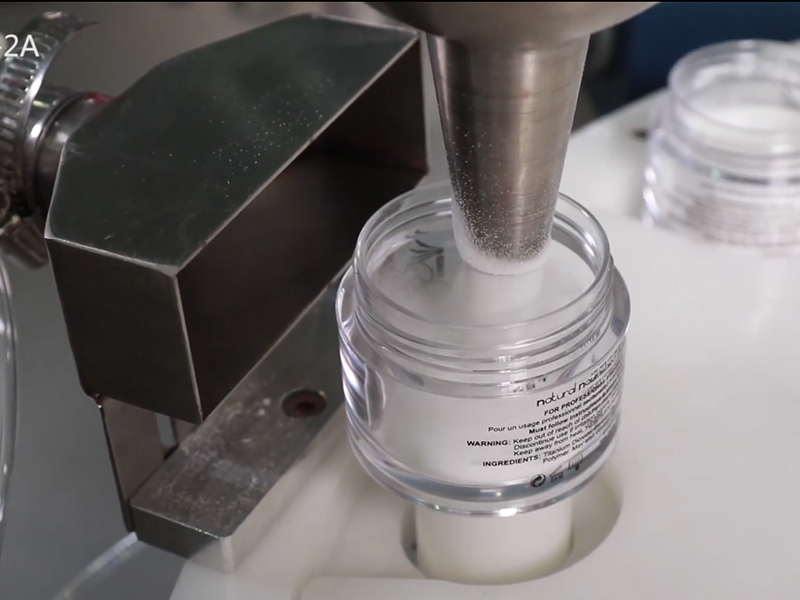

2. Improve filling accuracy: The semi-automatic liquid filling machine adopts advanced metering technology and control system, which can accurately control the filling volume of liquid. With preset parameters and automatic metering devices, it ensures that each container is filled with the exact amount of liquid, improving product consistency and quality.

3. Flexible to adapt to different products: The semi-automatic liquid filling machine has an adjustable design, which can adapt to different types of liquid products and container sizes. Through simple operation and adjustment, it can meet the filling requirements of different products, and can flexibly adapt to changes in the production line.

4. Reduce labor costs: Compared with fully manual filling, semi-automatic liquid filling machines can reduce manual participation. While still requiring operator monitoring and intervention, semi-automatic filling machines make operations easier and more efficient, reducing labor input and labor costs.

C. Application field of semi-automatic liquid filling machine

Semi-automatic liquid filling machines are widely used in the production of liquid products such as food, beverage, cosmetics, and medicine. Whether it is bottled beverages, oil products or cosmetics, semi-automatic liquid filling machines can complete the filling process quickly and accurately. It is especially suitable for small and medium-sized production lines, providing enterprises with cost-effective production solutions.

D. The function and significance of the semi-automatic liquid filling machine

The semi-automatic liquid filling machine plays a vital role in production and has the following important significance:

1. Improve production efficiency: Semi-automatic liquid filling machines can greatly improve production efficiency, enabling enterprises to meet market demand faster and improve market competitiveness.

2. Guarantee product quality: The semi-automatic liquid filling machine ensures the consistency and quality of the product through precise control of the filling volume, and avoids errors that may be introduced by manual filling.

3. Improve the convenience of operation: the operation of the semi-automatic liquid filling machine is relatively simple, the operator only needs to monitor and adjust, and does not require cumbersome manual operations, which reduces the burden on the operator.

4. Reduce production costs: Semi-automatic liquid filling machines can reduce labor input and labor costs, and do not require large equipment investment, which reduces the operating costs of enterprises.

As an efficient, accurate, economical and practical liquid filling equipment, the semi-automatic liquid filling machine has been widely used in many industries. It has the advantages of improving production efficiency, ensuring product quality, and reducing production costs, which is of great significance to the development of enterprises. Facing the pressure of market competition, enterprises should actively introduce semi-automatic liquid filling machines to improve production efficiency and product quality, and keep up with the pace of industry changes.