Release Date:2023-07-14 11:19:20 Popularity:

With the continuous advancement of science and technology, fully automated cosmetics production lines have gradually become the mainstream in the industry. This article will introduce the characteristics, application and future development trend of the fully automatic cosmetics production line in detail, so as to help readers better understand the latest developments in this field.

1. Features of fully automatic cosmetics production line

The fully automated cosmetics production line adopts advanced robot technology and automation equipment to realize the automation and efficiency of the production process. This production line has the following characteristics:

High efficiency: The fully automated production line greatly improves production efficiency by optimizing the production process and reducing manual intervention. For example, a traditional cosmetics production line can only produce a few hundred products per hour, while a fully automated production line can produce thousands of products per hour.

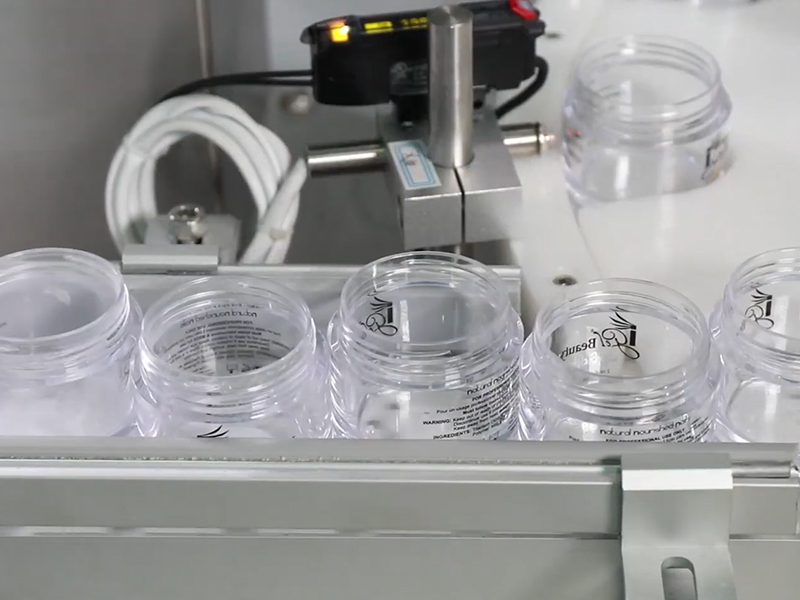

High precision: The fully automated production line uses high-precision equipment and sensors to ensure the accuracy and consistency of each production link. This helps to improve product quality and stability.

Reduce costs: Fully automated production lines can reduce labor costs, reduce waste and error rates in the production process, thereby improving production efficiency.

Strong controllability: The fully automated production line can monitor various data in the production process in real time through the central control system, adjust the production process in time, and ensure that the product quality meets the requirements.

2. Application of fully automatic cosmetics production line

Fully automated cosmetic production lines have been widely used around the world. The following are common application scenarios:

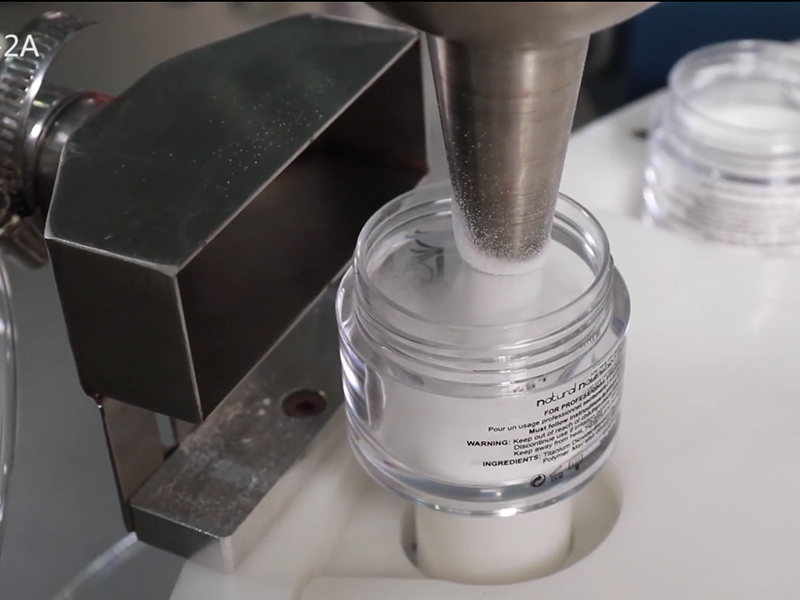

Skin care products: Fully automated production lines can efficiently produce various skin care products, such as creams, essences, lotions, etc. The production process of these products can be mixed, divided and packaged by automated equipment, thereby improving production efficiency.

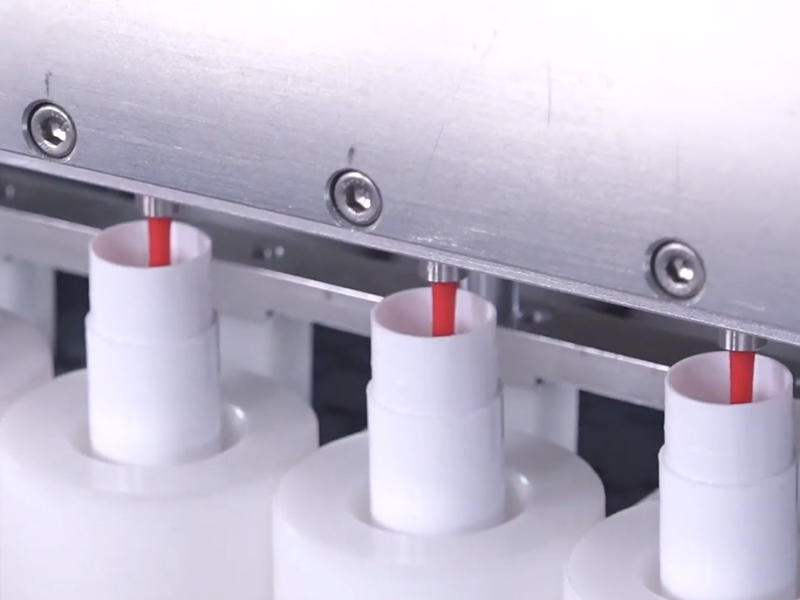

Cosmetics: The fully automated production line can also be used to produce various cosmetics, such as lipstick, eye shadow, foundation, etc. Mixing, pressing and packaging through automated equipment can ensure product quality and stability while improving production efficiency.

Fragrance products: The fully automated production line can produce all kinds of fragrance products, such as perfume, soap, shower gel, etc. Automation equipment can automate processes such as mixing, distillation and packaging, thereby reducing manual intervention and improving production efficiency.

Personal care products: The fully automated production line can also produce various personal care products, such as shampoo, conditioner, shower gel, etc. Through automated equipment for raw material mixing, pumping and packaging, etc., the production efficiency can be improved, the cost can be reduced, and the stability of product quality can be improved at the same time.

3. The future development trend of fully automatic cosmetics production line

With the advancement of science and technology and the constant changes of consumer demand, the future development trend of the fully automated cosmetics production line is as follows:

Intelligence: With the continuous development of artificial intelligence technology, the future fully automated production line will be more intelligent. By introducing artificial intelligence algorithms and big data analysis technology, the production line will be able to better predict market demand and consumer preferences, thereby optimizing the production process, improving production efficiency and reducing costs.

Sustainability: With the increasing awareness of global environmental protection, future fully automated production lines will pay more attention to sustainable development. For example, energy-saving equipment and environmentally friendly materials are adopted to reduce waste generation and increase the reuse rate of resources, thereby realizing green production.

Personalized customization: As consumers' demand for personalized products increases, future fully automated production lines will pay more attention to personalized and customized production. Through a flexible production system and advanced formulation technology, product diversification and small batch production are realized to meet consumers' individual needs.

Safety and quality improvement: While pursuing high efficiency, future fully automated production lines will pay more attention to product safety and quality improvement. By strengthening quality monitoring and establishing a sound quality management system, we ensure that products meet relevant regulations and consumer safety requirements.

In short, the fully automated cosmetics production line, as a product of the combination of modern technology and the cosmetics industry, has the characteristics of high efficiency, precision, and strong controllability. With the continuous advancement of technology and the continuous change of consumer demand, the fully automated production line in the future will be more intelligent, sustainable, personalized and safer. It is believed that with the continuous improvement and development of fully automated technology, the cosmetics industry will usher in a better future.