Release Date:2023-09-16 10:11:32 Popularity:

In today's era, bottled water is in increasing demand as a convenient and safe source of waste water. In order to meet the market demand and improve the production efficiency, more and more enterprises start to adopt fully automatic bottled water production line. This production line can not only reduce labour cost, but also improve production efficiency and product quality.

Fully automatic bottled water production line is a highly automated production process, all the links from water loading, bottle blowing production, filling, handling and sealing to labelling and palletising can be completed by one production line. The production line has the following characteristics:

High automation: the whole production process needs almost no human intervention, from bottle blowing, packing, sealing to labelling and palletising can be done automatically by machines.

High efficiency: the bottled water production line adopts the most advanced production process and equipment, which makes the production efficiency increase greatly and can meet the market demand quickly.

Advantage: Due to the high degree of automation, the labour cost in the production process is greatly reduced, and it can also reduce the waste in the production process and lower the production cost.

Stable quality: the use of bottled water production line can ensure that the product quality is more stable, to avoid the impact of human influence on product quality.

Automatic bottled water production line is mainly composed of the following parts:

Water treatment equipment: this is the first step of the bottled water production line, mainly including filtration, disinfection and other stages to ensure that the water quality meets the standard.

Bottle blowing and completing equipment: this process is to fill the treated water into bottles.

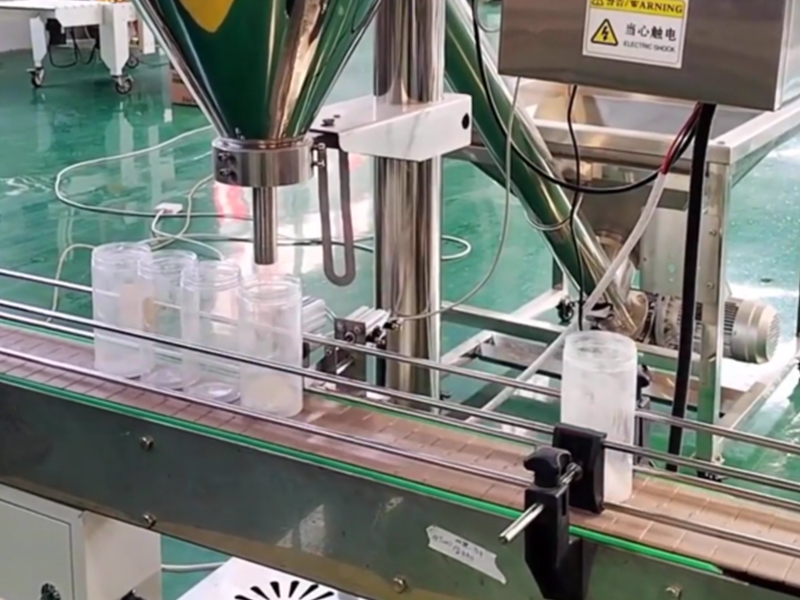

Filling equipment: Fill the water inside the bottles to a certain weight or volume to ensure that the amount of water in each bottle is consistent.

Sealing equipment: After the packaging is completed, the bottles need to be sealed quickly to prevent water evaporation and contamination.

Labelling equipment: Put appropriate labels on the bottles, including production date, shelf life, brand and other information.

Palletising equipment: the labelled bottles are stacked in shelves or cartons according to requirements, followed by subsequent transport and storage.

Bottled water production line is suitable for all sizes of enterprises, whether it is a large mineral water producer or a small wastewater plant, can improve production efficiency, reduce costs and ensure product quality through this production line. In the actual production and application of which, automatic bottled water production line has the following advantages and significance:

Improve production efficiency: automatic bottled water production line can greatly improve production efficiency, reduce production time, so as to quickly meet market demand.

Reduce costs: high degree of automation can reduce labour costs, but also reduce the waste and loss caused by human factors.

Improve product quality: bottled water production line can ensure the stability and consistency of product quality, to avoid the impact of human-related product quality.

Reduce environmental pollution: compared with traditional manual production lines, bottled water production lines can reduce consumption and pollution of production, more environmentally friendly and sustainable.

Bottled water production line may have some problems and failures in the application, such as equipment failure, sensor false alarms, circuit failures and so on. In order to guarantee the stable operation of the equipment, here are some countermeasures:

Regular maintenance: carry out regular maintenance and repair of the equipment on the production line to ensure the normal operation of the equipment.

Troubleshooting: When equipment failure occurs, we should investigate the cause in time and take corresponding measures to solve the problem.

Sensor check: Regularly check the working status of the sensor to ensure its accuracy and reliability.

Circuit checking: Regularly check whether the circuit is normal or not, to prevent circuit failures from affecting the production line.

Emergency plan: For possible emergencies, make corresponding emergency plan to the smooth running of production.

In general, bottled water production line has a high status and wide application value in industrial production. It can improve production efficiency, reduce costs, improve product quality, reduce environmental pollution and other advantages. In the future, with the continuous development of science and technology, the automatic bottled water production line will develop in the direction of more standardisation to achieve more efficient and accurate control and production. At the same time, as people's demand for railway quality continues to improve, automatic bottled water production line will also focus on more environmentally friendly, healthy production methods and technology development.