Release Date:2023-09-21 10:43:14 Popularity:

In today's manufacturing sector, non-standard automated production line manufacturers are emerging as industry leaders. These manufacturers are able to provide customized smart manufacturing solutions to automate, informatize, and intelligentize the production process according to customer needs. In this article, we will discuss in detail the advantages of non-standard automation production line manufacturers, choosing the right manufacturer and the future development trend in the era of Industry 4.0.

First, the definition and introduction of non-standard automation production line manufacturers

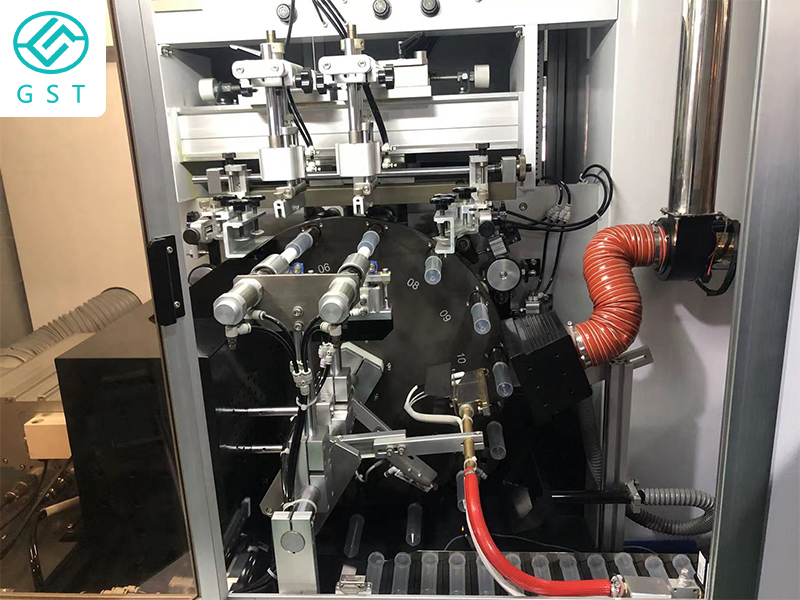

Non-standard automation production line manufacturers are enterprises specializing in the design, development, manufacture and commissioning of non-standard automation production lines. The biggest difference between them and traditional assembly line manufacturers is that non-standard automation production line manufacturers are able to provide personalized intelligent manufacturing solutions to meet the needs of different product production according to the needs of customers. In the field of intelligent manufacturing, non-standard automation production line manufacturers play an increasingly important role.

Second, the advantages and significance of non-standard automation production line manufacturers

Flexibility: non-standard automation production line manufacturers have the ability to provide customized solutions for the production of different types of products. This means that they can quickly adapt to market changes and meet the diverse needs of customers.

Energy-saving and emission reduction, improved productivity: through intelligent transformation, non-standard automated production line manufacturers can make the production process more energy-saving and environmentally friendly, while improving productivity. For example, through the introduction of robots and automated equipment, manual intervention can be reduced, the error rate can be reduced, and production can be increased.

Expanding sales channels and brand awareness: non-standard automation production line manufacturers can provide customers with diversified products and services, thus expanding sales channels and enhancing brand awareness.

Third, how to choose the right non-standard automation production line manufacturers

When choosing a non-standard automation production line manufacturer, you need to consider the following factors:

Qualification: Check the manufacturer's business license, tax registration certificate, organization code certificate and other qualification documents to ensure that it has legal business qualifications.

Reputation: understand the manufacturer's market reputation and customer evaluation, you can search the Internet, industry associations recommend the way to get relevant information.

Service: Consider the manufacturer's pre-sales consulting, program design, installation and commissioning, after-sales service and other one-stop service capabilities. Ensure that manufacturers can provide services to meet your needs.

Price: Compare the offers of different manufacturers and choose the one with higher cost performance. At the same time, pay attention to the price is not the only determining factor, quality and service are equally important.

Fourth, the future development of non-standard automation production line manufacturers in the era of industry 4.0

In the era of Industry 4.0, digitalization, intelligence and globalization have become the trend of manufacturing development. Non-standard automation production line manufacturers will face more opportunities and challenges. In order to adapt to this change, non-standard automation production line manufacturers need to take the following measures:

Strengthen technological innovation: constantly introduce new technologies and processes, and strengthen technological research and innovation in order to improve production efficiency and product quality.

Promote digital transformation: apply advanced technologies such as Internet of Things, big data, cloud computing, etc., to realize digital management and intelligent control of the production process, and improve production efficiency and enterprise competitiveness.

Expand international markets: actively participate in international cooperation and competition, expand overseas markets, and enhance the international influence of brands.

Focus on sustainable development: pay attention to environmental protection and resource utilization, implement green manufacturing and low-carbon economy, and contribute to the realization of sustainable development.

In short, non-standard automation production line manufacturers as the core force of intelligent manufacturing, in the future development will usher in a broader stage. Only by constantly adapting to market changes, strengthening technological innovation, expanding the international market, and focusing on sustainable development, can we stand invincible in the fierce market competition.