Release Date:2023-12-09 11:46:05 Popularity:

With the rapid development of science and technology, automation technology has penetrated into various fields. Among them, automated packaging production lines have been widely used in recent years. The emergence of this technology not only improves production efficiency and reduces production costs, but also lays the foundation for the industrial upgrading of enterprises. This article will conduct an in-depth analysis of the automated packaging production line and discuss its development status, advantages and future trends.

1. Development status of automated packaging production lines

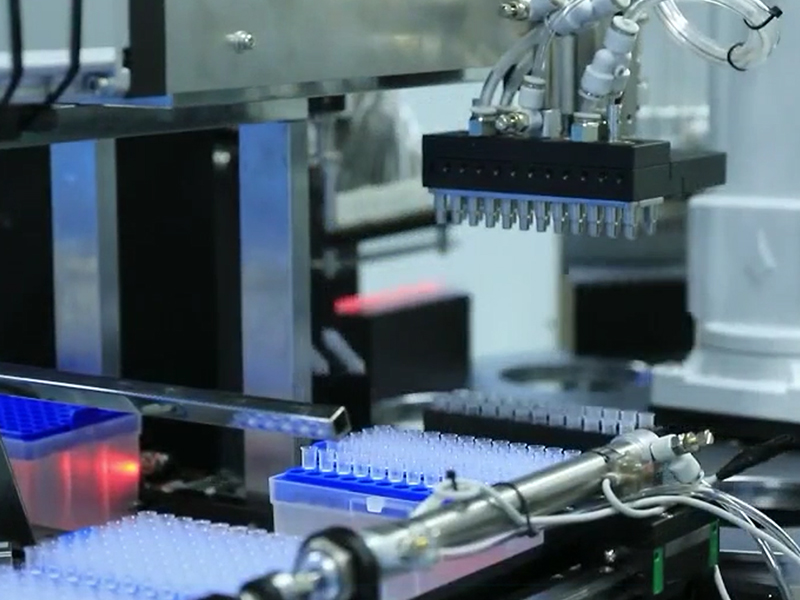

The automated packaging production line is an automated system that integrates optical, mechanical, electrical, gas, liquid, magnetic, instrument and other technologies. In the packaging industry, the application of this technology has become very common. At present, major packaging companies around the world are actively investing in research and development to promote the development of automated packaging production lines.

Domestically, the development of automated packaging production lines has also made great progress. Many companies have developed automated packaging equipment suitable for the domestic market by introducing advanced foreign technology and combining it with local realities. At the same time, some large enterprises have also cooperated with scientific research institutions to deeply optimize automated packaging production lines and realize the automation and intelligence of the entire packaging process.

2. Advantages of automated packaging production lines

Improve production efficiency: The automated packaging production line has the characteristics of high efficiency and stability, which can greatly improve production efficiency. In the traditional packaging model, there are many manual steps involved and are easily affected by human factors, resulting in low production efficiency. The automated packaging production line can realize full process automation, avoiding the occurrence of human factors and ensuring the stability and efficiency of production.

Reducing costs: Automated packaging production lines have significant advantages in reducing costs. First of all, the operating cost of automated equipment is lower than labor cost; secondly, automated packaging production lines can reduce labor input and reduce labor costs; finally, automated equipment can work continuously, reducing downtime caused by human factors, further reducing production costs .

Improve product quality: The automated packaging production line uses high-precision, highly stable automation equipment, which can greatly improve product quality. In addition, through the monitoring and detection functions of automated equipment, the entire production process can be monitored, problems can be discovered and dealt with in a timely manner, and the quality of the product can be further guaranteed.

Enhance corporate competitiveness: Automated packaging production lines have the advantages of high efficiency, low cost, and high quality, which can help companies improve their market competitiveness. In today's fierce market competition, companies can only remain invincible in the market through continuous technological innovation and equipment updating.

3. Future trends of automated packaging production lines

Highly intelligent: Future automated packaging production lines will develop in a highly intelligent direction. By introducing technologies such as artificial intelligence and the Internet of Things, we can realize functions such as independent decision-making, self-healing and remote monitoring of equipment, further improving the reliability and stability of the production line.

Multifunctionality: The future automated packaging production line will no longer have a single packaging function, but a comprehensive production line with multiple functions. For example, packaging equipment can integrate detection, marking, coding and other functions to achieve multiple uses in one machine and improve the utilization rate of the production line.

Green and environmental protection: Future automated packaging production lines will pay more attention to environmental protection and sustainable development. Reduce energy consumption and environmental pollution during the production process by using environmentally friendly materials, optimized design, and energy-saving technologies.

Cloudization: The future automated packaging production line will be closely integrated with cloud computing, big data and other technologies to achieve cloud storage and analysis of production data. By monitoring and analyzing production line data in real time, companies can accurately control and optimize the production process.

In short, automated packaging production lines are the development trend of the future packaging industry. With the continuous advancement and innovation of technology, we have reason to believe that future automated packaging production lines will be more efficient, intelligent, environmentally friendly and multi-functional, providing strong support for the industrial upgrading and sustainable development of enterprises.