The automatic pipette leak detector is an intelligent testing device specifically developed for lab consumables manufacturers, primarily used for testing the seal and airtightness of disposable plas

The automatic pipette leak detector is an intelligent testing device specifically developed for lab consumables manufacturers, primarily used for testing the seal and airtightness of disposable plastic pipettes. Through automated loading, precise inspection, and intelligent rejection, the device quickly screens out pipettes with defects such as leaks and poor seals, ensuring product stability and reliability. It not only effectively improves inspection efficiency but also significantly reduces manual inspection errors, making it an ideal device for quality control in lab consumables manufacturers.

Key Features:

High-Precision Inspection: Utilizing an advanced airtightness detection system, it accurately detects even the smallest leaks, ensuring that every pipette meets sealing standards.

Automated Operation: The entire process, from loading, inspection, determination, to defective product rejection, is automated, significantly reducing manual intervention.

Intelligent Control: Equipped with a PLC control system and touchscreen interface, the system allows for flexible configuration of inspection parameters and intuitive and convenient operation.

High-Efficiency Screening: Supports simultaneous inspection at multiple stations, significantly improving inspection efficiency and meeting the needs of large-scale production.

Strong Compatibility: Compatible with pipettes of varying sizes and capacities, and customizable to meet diverse testing scenarios.

Stable and Reliable: Core components are constructed of high-quality materials, ensuring stable testing performance over extended periods of operation.

Application Value:

Quality Assurance: Prevents substandard pipettes from entering the market, enhancing product reputation and market competitiveness.

Efficiency Improvement: Compared to manual testing, efficiency is several times higher, supporting 24/7 operation.

Cost Reduction: Reduces the manpower required for manual testing, while minimizing rework and post-sales risks.

Enhancing Compliance: Meets the stringent testing standards of the laboratory consumables and medical device industries, helping companies upgrade their quality management systems.

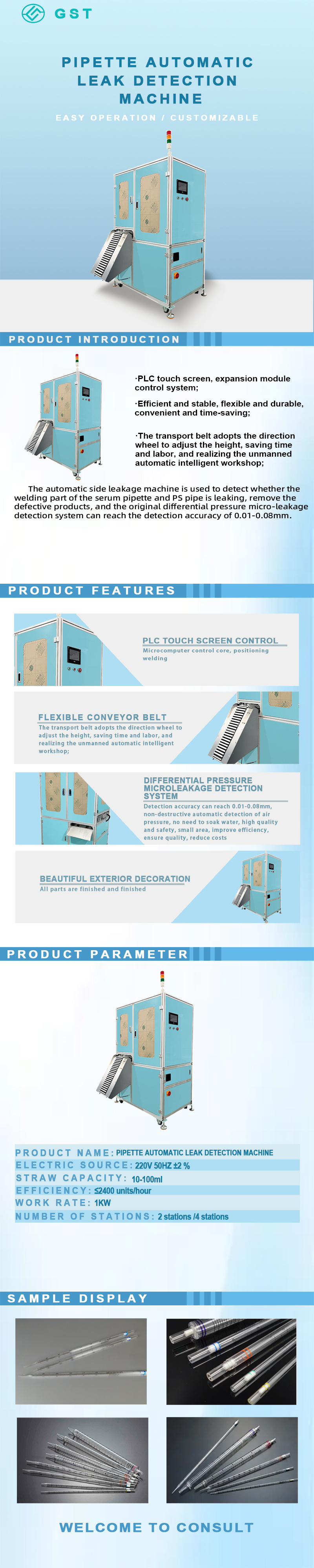

Automatic side leakage machine is used to detect whether serum pipettes and PS tubes are leaking at the welding part and take out the defective products.

Equipment features:

Pipette automatic leakage detection, automatic removal of defective products.

Technical Parameters:

Model: GST-YYG104A

Pipette capacity: 10-100ml

sizes: 170*1500*1850mm

production capacities: 2000-2400pcs/h

power (output): 1KW

Customized Support: Yes