Product Overview: The automatic ultrasonic pipette welding machine is a high-precision automated welding device specifically developed for laboratory consumables manufacturers. It utilizes high-fre

Product Overview:

The automatic ultrasonic pipette welding machine is a high-precision automated welding device specifically developed for laboratory consumables manufacturers. It utilizes high-frequency ultrasonic vibrations to instantly generate molecular-level frictional heat in pipette components, achieving a secure weld. Featuring high efficiency, high precision, and a pollution-free design, this machine is widely used in medical devices, in vitro diagnostics (IVD), biological laboratory consumables, and other fields.

Core Advantages:

1. High Welding Precision: Utilizing advanced ultrasonic welding technology, it ensures secure welds and excellent sealing, eliminating the risk of leaks.

2. High Automation: It integrates automatic loading, precise positioning, welding, and unloading, significantly improving production efficiency.

3. Easy Operation: Equipped with an intelligent PLC control system and touchscreen interface, parameters can be set and saved with a single click.

4. Stable Quality: Fully automated inspection eliminates errors caused by manual operation and improves product consistency.

5. Environmentally Friendly: Requires no additional adhesives or heating, resulting in a clean and environmentally friendly welding process that complies with GMP and CE standards.

Technical Features:

The ultrasonic frequency is stable, the welding speed is fast, and a single machine can replace multiple workers.

The welded joint is aesthetically pleasing, burr-free, and does not affect the performance of the pipette.

Customizable according to customer needs, supporting the welding of various pipette specifications.

Supporting networking and data collection capabilities facilitates intelligent production management for enterprises.

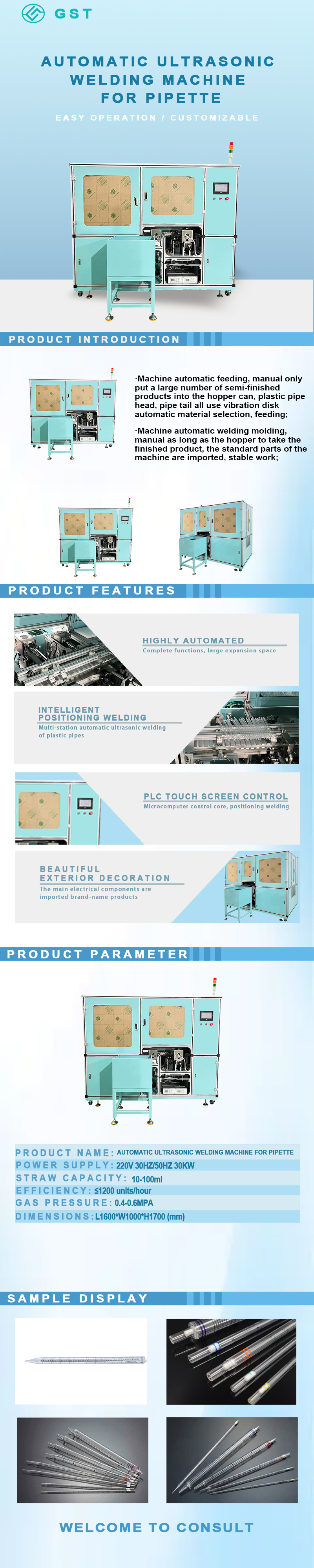

This automatic ultrasonic welding machine is used for automatic positioning and automatic welding of plastic tubes, PS tubes and pipettes.

Equipment features:

1) Automatic feeding.

2) Tube head and tube tail all adopt vibrating disk to select and feed materials automatically;

3) Fully automatic welding molding.

4) The standard parts of the machine adopt imported brands.

5) All parts adopt surface treatment, exquisite and generous.

Technical Parameters:

Equipment Model: GST-YYG103A

Pipette capacity: 10-100ml (1 set of equipment can only process a capacity of the pipette)

Ultrasonic equipment: Taiwan brand Evergreen 15-20K

sizes: L2500xW1500xH1200 (mm)

production capacities: 1100-1200 pcs/hour

power (output): 4.3KW

Customized Support: Yes