The trouser hanger automatic assembly machine is a highly efficient automated assembly device specifically developed for clothing hanger and trouser rack manufacturers. It integrates multiple proces

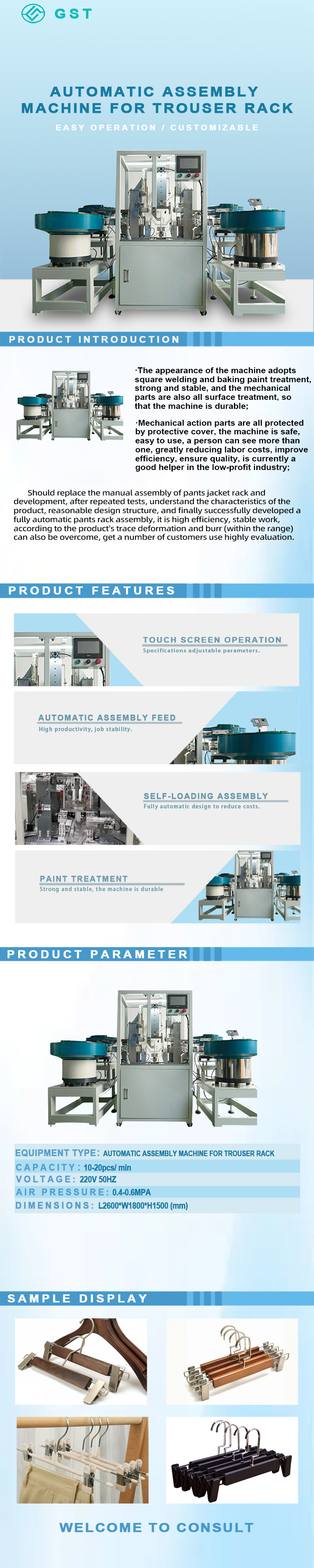

The trouser hanger automatic assembly machine is a highly efficient automated assembly device specifically developed for clothing hanger and trouser rack manufacturers. It integrates multiple processes, including automatic loading, precise positioning, rapid assembly, and automated inspection, enabling fully automated assembly of trouser hanger components and accessories (such as hooks, clips, and sliders). This significantly improves production efficiency and product consistency while reducing labor costs.

The machine utilizes a PLC intelligent control system and high-precision servo drive, combined with a multi-station automated structure, enabling stable and efficient assembly of various trouser hangers. The entire machine frame is constructed of high-quality steel and wear-resistant components, ensuring smooth operation, low noise, and a long lifespan. The touchscreen interface is user-friendly, allowing for quick parameter adjustments based on different trouser hanger specifications, meeting the diverse production needs of manufacturers.

Key Advantages:

High Efficiency: Multi-station simultaneous operation enables fast assembly, making it suitable for large-scale production.

High Precision: Automatic positioning and precise assembly ensure a high product yield.

Multi-Specification Compatibility: Supports automated assembly of various types and sizes of trouser hangers and accessories.

Intelligent Control: A touchscreen interface provides adjustable parameters and real-time monitoring of production status.

Cost Reduction: Reduces manual labor and improves production standardization and automation.

Application Areas:

It is widely applicable to manufacturers of various types of hanger accessories, including plastic, wooden, and metal trouser hangers. It is particularly well-suited for assembly line production in large and medium-sized factories, significantly improving production efficiency and market competitiveness.

Technical parameters:

model number: GST-WJ009A

Voltage: 220V AC 50HZ

Air pressure: 0.4-0.6MPA

Working efficiency: 10-20/minute

Dimension: L2600*W1800*1500H

Customized Support: Yes