The O-ring automatic assembly machine is a highly efficient automated assembly device developed for the seals, valves, and automotive parts industries. It is specifically designed for the precise as

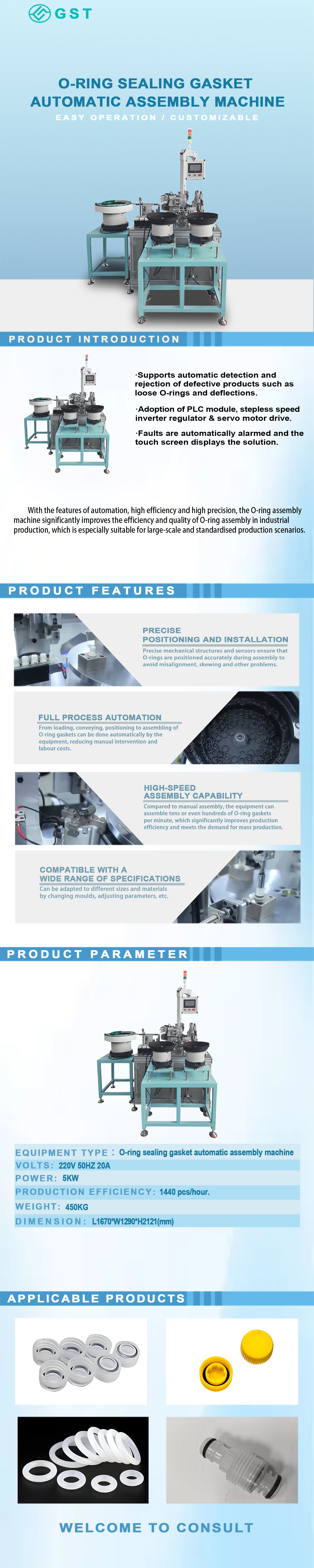

The O-ring automatic assembly machine is a highly efficient automated assembly device developed for the seals, valves, and automotive parts industries. It is specifically designed for the precise assembly of rubber/silicone gaskets, such as O-rings and sealing rings. Equipped with a PLC and touchscreen intelligent control system, the machine automatically loads, positions, inspects, and presses. A single-button start allows for high-precision, high-speed assembly, significantly improving production efficiency and reducing labor costs.

This compact machine, with a small footprint, features a multi-station rotary table and a vision positioning system, enabling rapid switching between O-rings of varying specifications. It also includes built-in low-material detection, assembly defect alarms, and automatic rejection of defective products to ensure product quality and reliability. Made primarily of high-quality carbon steel or stainless steel, the machine is durable and meets the requirements of industrial-grade, long-term continuous production.

This O-ring automatic assembly machine not only significantly improves assembly speed and consistency, but also improves the workshop work environment, reduces human error and material waste, and lays a solid foundation for companies to achieve automated and intelligent production. Whether in the automotive, machinery, home appliance, or precision instrument industries, it is an ideal choice for achieving large-scale production and improving quality.

model number: GST-WJ012A

sizes: L1670*W1290*H2121(mm)

production capacities: 1440pcs/h

power (output): 220V/50HZ 20A 5KW

Customized Support: Yes