The syringe automatic assembly machine is a highly efficient, intelligent assembly device specifically developed for medical consumables manufacturers. It performs automated feeding, precise positio

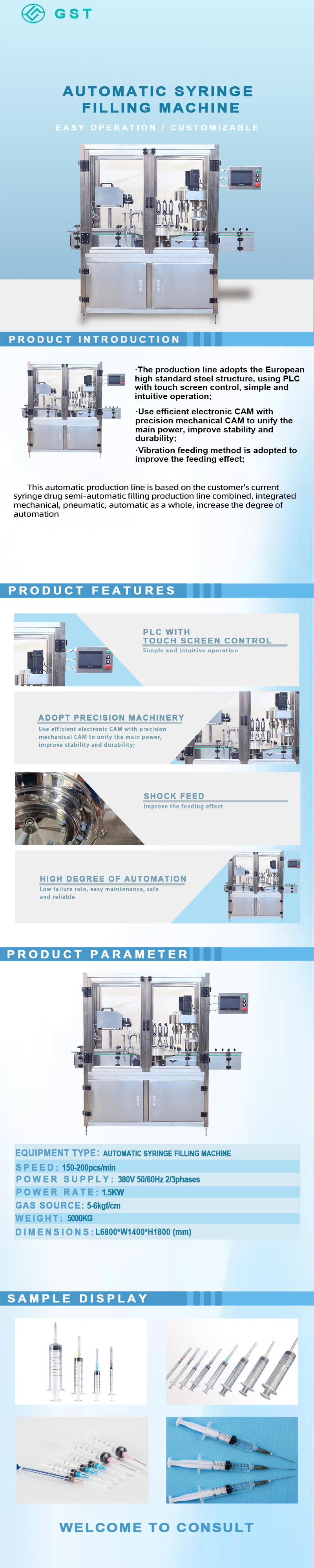

The syringe automatic assembly machine is a highly efficient, intelligent assembly device specifically developed for medical consumables manufacturers. It performs automated feeding, precise positioning, automated assembly, and inspection of syringe barrels, plungers, pistons, and needle caps, significantly improving production efficiency and product consistency. The machine features a modular design, integrating robotic gripping, servo drive, vision positioning, and in-line inspection. It maintains stability and high precision during high-speed operation, reducing human error and ensuring the safety and quality of syringe products.

The entire machine frame is constructed of stainless steel and aluminum, meeting GMP clean production requirements. The control system utilizes a PLC and human-machine interface (HMI), offering intuitive operation and quick parameter adjustment. The syringe automatic assembly machine can be flexibly configured with functional modules such as automatic loading, in-line vision inspection, defective product rejection, and automatic packaging to meet customer needs, enabling one-stop production management.

This equipment is widely applicable to the large-scale production of medical syringes, prefilled syringes, and similar consumables, significantly reducing labor costs, improving product yields, and enhancing traceability. It is an ideal choice for medical device companies to implement intelligent manufacturing and enhance market competitiveness.

Technical parameters:

Model number: GST-BC001

Power supply: 380VAC, 50/60Hz, 2/3 phase.

Power: 1.5kw

Working speed: 150-200pcs/min

Machine weight: 5000kg

Air source: 5-6kgf/cm².

Overall Dimension: L6800*W1400*H1800mm

Customized Support: Yes