The semi-automatic pipette tip cartoning machine is a highly efficient cartoning machine designed specifically for laboratory consumables manufacturers. It is primarily used for the automated carton

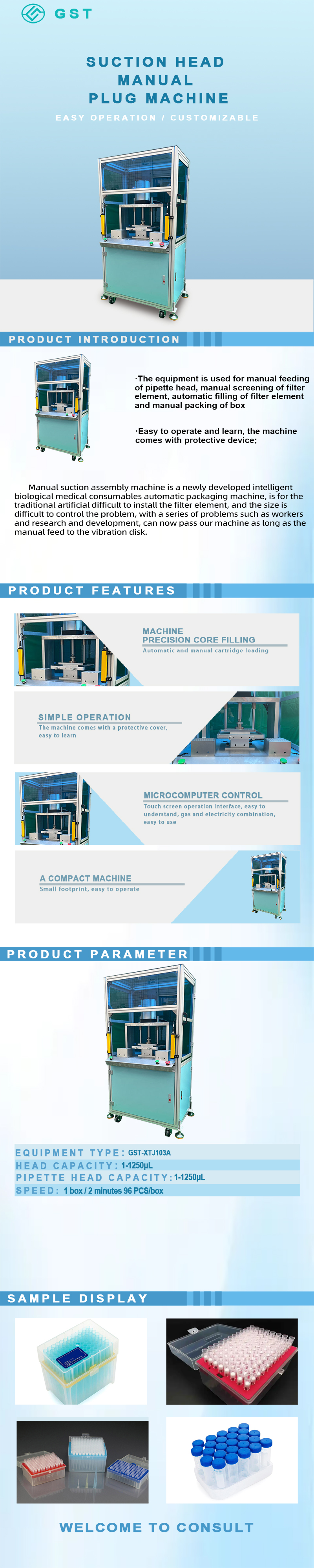

The semi-automatic pipette tip cartoning machine is a highly efficient cartoning machine designed specifically for laboratory consumables manufacturers. It is primarily used for the automated cartoning, sorting, and counting of pipette tips and other small tubing components prior to cartoning. The machine utilizes a semi-automatic control mode, combining precise automation with flexible manual operation to ensure both production efficiency and ease of operation.

Equipped with precision sensors and an adjustable conveyor mechanism, the machine automates the steps of tip alignment, cartoning, pushing, and cartoning, significantly reducing manual operation time and improving product consistency. Its modular design facilitates mold and format changes, accommodating pipette tip products of varying sizes and packaging requirements. The touchscreen human-machine interface (HMI) allows operators to easily set parameters, monitor production status in real time, and support data logging and statistics.

The semi-automatic pipette tip cartoning machine is particularly suitable for small- to medium-volume, multi-format production, providing a cost-effective solution that bridges the gap between manual and fully automated production. It can effectively reduce labor costs and error rates, and can be used online with subsequent automatic labeling, carton sealing and other equipment to help experimental consumables manufacturers achieve streamlined and standardized production management, and improve market response speed and competitiveness.

Technical parameters:

Equipment Model: GST-XTJ103A

Tip capacity: 1-1250μL

Sizes: 360*320*5250px

Production capacities: 1 box/minute 96 pcs/box

Power (output): 1.5kw

Customized Support: Yes