The Multi-Dose Test Card Automatic Assembly Machine is a highly efficient, automated production machine designed specifically for the in vitro diagnostic (IVD) industry. It automates the entire proc

The Multi-Dose Test Card Automatic Assembly Machine is a highly efficient, automated production machine designed specifically for the in vitro diagnostic (IVD) industry. It automates the entire process of assembling multi-dose test card strips, from raw materials to finished product.

Integrating multiple technologies such as precision sensing, visual inspection, and intelligent control, the machine performs processes such as feeding, positioning, laminating, pressing, inspection, rejection, and counting at high speed, significantly improving production efficiency and yield.

This machine is suitable for producing test cards of various specifications and multiple workstations. Its modular structure facilitates rapid product changeover, flexibly meeting individual customer needs.

Utilizing a high-precision servo system and a human-machine interface (HMI), operators can easily set parameters, monitor the production process, and automatically generate production data reports, helping companies achieve quality traceability and information-based production management.

The Multi-Dose Test Card Automatic Assembly Machine not only reduces manual labor and improves production consistency, but also seamlessly integrates with upstream and downstream equipment to form a complete automated production line.

An ideal choice for laboratories and medical device manufacturers to enhance production capacity and quality control, it helps reduce labor costs, shorten delivery cycles, and enhance market competitiveness.

Product features:

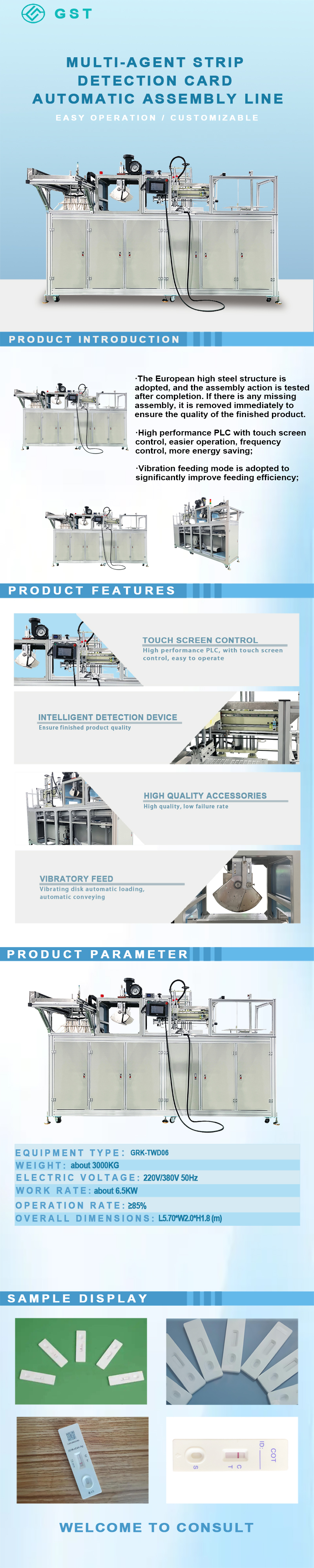

1. Adopt European high-strength structure;

2. Adopt high-performance PLC with touch screen control, which is easier to operate, and adopts variable frequency speed regulation, which is more energy-saving;

3. Adopt vibration feeding method to significantly improve feeding efficiency;

4. There is detection after the assembly action is completed. If there is any missing assembly, it will be removed immediately to ensure the quality of the finished product;

5. All electrical equipment accessories and pneumatic device accessories of the whole machine are from well-known foreign brands, with excellent quality and low failure rate;

6. The machine realizes "card box conveying": the bottom card and the surface card vibration plate are automatically loaded, and the bottom card and the surface card are automatically conveyed;

7. Large board conveying: large board is automatically loaded;

8. Image quality inspection:

1) Identification of defects in the bottom card material of plastic cards;

2) Identification of defects in the surface card material of plastic cards;

3) Identification of NC film defects, dirty strips, narrow strips, and waste strips of test strips after cutting;

4) Identification of the position of the test strip after it enters the bottom card;

5) Identification of the position of the test strip after the surface card is closed;

6) Defect recognition and elimination: automatic.

Device parameters:

model number: GRK-TWD06

sizes: L5.70*W2.0*H1.8 (m)

weight:3000KG

production capacities: 2400pcs/H

power (output): 6.5kw

Customized Support: Yes