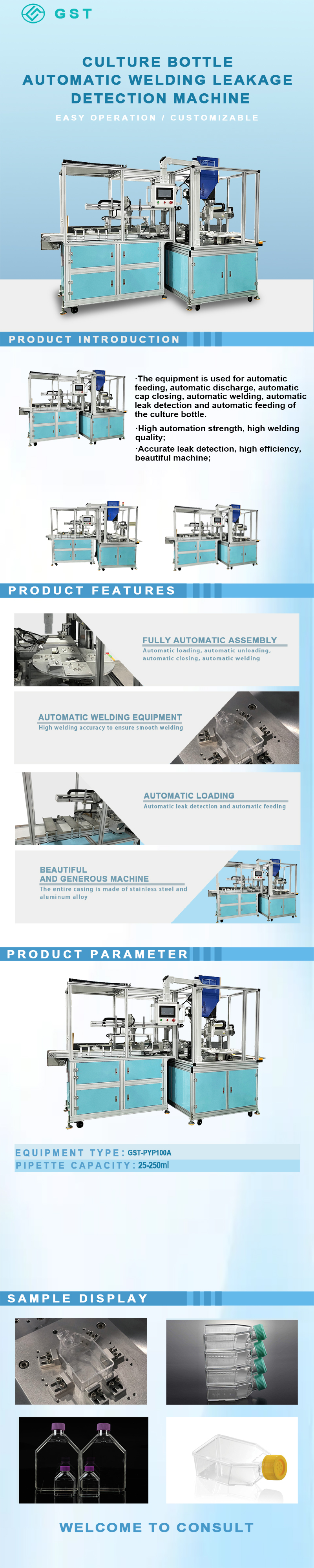

The Ultrasonic Weld Leak Detector for Culture Bottles is a high-precision automated testing device specifically developed for the medical and laboratory consumables industries. It is primarily used

The Ultrasonic Weld Leak Detector for Culture Bottles is a high-precision automated testing device specifically developed for the medical and laboratory consumables industries. It is primarily used to test the sealing performance of culture bottles after ultrasonic welding.

The device utilizes advanced ultrasonic welding technology combined with airtightness testing technology to ensure secure welds and reliable seals for culture bottles while operating at high speeds, preventing product rejection due to air leaks or liquid seepage.

The device supports rapid switching between multiple culture bottle sizes and offers advantages such as ease of operation, high detection sensitivity, and robust stability. The entire device is intelligently controlled by a PLC and equipped with a human-machine interface operating system, enabling real-time data monitoring and recording, facilitating production traceability and quality control.

The Ultrasonic Weld Leak Detector for Culture Bottles not only improves production efficiency and product qualification rates, but also effectively reduces manual testing costs, providing a safe, efficient, and reliable solution for medical consumables manufacturers.

Equipment features:

1) High automation intensity; 2) High welding yield; 3) Accurate leakage detection and high efficiency; 4) Beautiful machine.

Technical parameters:

Equipment Model: GST-PYP100A

Freezing tube capacity: 25-250ml

sizes: L2550*W2000*H1500(mm)

production capacities: 600pcs/h

power (output): 1.5kw

Customized Support: Yes